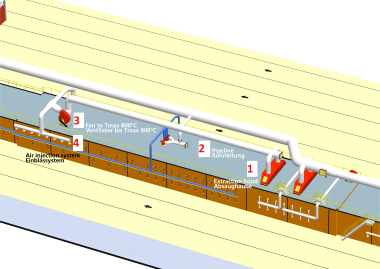

HF-Absorb dry sorption process

Since the use of Ca(OH)2 as reagent in the dry-sorption modules yields high levels of efficiency (up to 95%), the relatively high cost of the reagent remains acceptable and economical. The resultant end product consists primarily of fluorspar and fractions of unreacted lime hydrate.

The reactors have no moving parts, cause little loss of pressure and require no manpower for maintenance and spare-part installation. The HF-Absorb system is easy to handle and cost-efficient.

An HF-Absorb system becomes particularly attractive economically, when the kilns‘ operating conditions are changed, e.g., when kilns with a continuous operating mode are replaced with an intermittent type, or when kilns are shut down during the winter time. This exposes a central absorption plant to different load levels or even temporary shutdown with resultant condensation problems and attendant conglutination of the granulated lime.

No dust filters are required for an HF-Absorb system as long as the flue gas temperature remains above the dew point (max. 350° C, or 300° C for continuous operation). The lime modules are quick and easy to install and extract on stacking pallets. The same applies to replacing spent lime modules.