Albrecht Türrschmiedt – the forgotten brickmaker

When people get to talking about how brickmaking evolved from a trade to an industry, the likes of Friedrich Hoffmann, Carl Schlickeysen, Georg Mend-heim, Jacob Bührer, Otto Bock and Professor August Hermann Seger are usually mentioned, but who ever thinks of Albrecht Türrschmiedt? He, though, also counts among the leading pioneers of brickmaking technology. Türrschmiedt was known not for any trailblazing inventions, but for his tireless theoretical and practical elucidations, presentations and publications. He gave brickmakers, potters, lime and cement producers what they needed for adopting and mastering all the new technologies, and he helped form an intellectual basis for the revolutionary transformation from trade to industry.

1 Introduction

Albrecht Türrschmiedt added not only pretty music and poetry to the sounds of brickmaking, but also the huff and puff of hard-working steam engines, the rattle and clank of processing units, the squeak and squeal of V-belts, the murmur and mumble of extruders, the whiz and whirl of the kilns‘ fans, all coupled with the rumble and tumble of little transfer cars with their heavy loads. They all helped round out an orchestra of work playing a symphony conducted by well-experienced specialists.

Obsessed with the theory and practice of ceramics in general and of brickmaking technology in particular, Albrecht Türrschmiedt was the right man at the right place at the right time in Berlin, when Friedrich Hoffmann invented his “ring oven“ and Carl Schlickeysen his auger press. He, who liked to spend his leisure time relaxing at his piano‘s keyboard or singing at Berlin‘s Singe-Academie (founded in 1791 by Carl Friedrich Christian Fasch [1736–1800] and now known as the singakademie), emerged as Friedrich Hoffmann‘s and Carl Schlickeysen‘s key partner and aide. With his vast knowledge of the natural sciences and massive practical experience, Türrschmiedt engaged in an intensive, continuous study of pertinent literature, continued education and a string of major travels to help the then-nascent modern brickmaking technology make its breakthrough.

2 Musician-cum-natural scientist

Born in Berlin on May 16, 1821, as the son of the professional musician and music teacher Carl Nikolaus Türrschmiedt and his wife, concert singer and singing teacher Auguste Türrschmiedt, Albrecht soon developed a lifelong love of music and the fine arts. Despite being a musician in his own right, he always remained a dilettante compared to his parents and grandparents, all of whom were well-known in Berlin. His domicile on Pariser Platz, which he shared with his sister Theresa, was adorned with valuable paintings, ceramics and sundry works of art and served as a frequent venue for evenings of music with friends and acquaintances. His greatest interest, however, was in science and technology.

After graduating from secondary school in Berlin-Cölln around 1838, he completed his obligatory military service with the Prussian Engineers of the Guard. He then learned the art of pottery as an apprentice to master potter and pottery manufacturer Tobias Christoph Feilner (1773–1839), who with his 120 employees significantly influenced the Berliner brickwork artistry of Friedrich Schinkel. At the same time, he was also studying the natural sciences at what was then Berlin‘s Friedrich Wilhelm University – now Humboldt University. After several semesters, Türrschmiedt accepted a position at a brick factory in Hermsdorf, northwest of Berlin, and, in 1847, hired on as manager of the brick factory at his brother-in-law‘s estate in Ruhnow, Eastern Pomerania. In the wintertime, he pursued intensive, in-depth studies of chemistry, physics, geology and mineralogy. In 1857, he leased a brick factory in Neustadt-Eberswalde and did quite well at first, but was eventually so buffeted by a protracted economic downturn, that he could no longer stand up to the pressure: In 1865, poor health forced him to give up the lease.

Before that, in 1857 to be exact, he joined a group of like-minded men in Eberswalde to found a polytechnical society and published a technical journal on drainage for roughly four years. In the mid-19th century, drain pipes were one of the most important products of brick factories in the Kingdom of Prussia.

On an extended journey through Belgium, France, Great Britain and Holland in 1858, Türrschmiedt expanded his perception of brick production problems. Providing consultancy for a new brick factory situated outside of Berlin‘s Rosenthal Gate, he became embroiled in a heated debate with the project‘s sponsors about brickyard productivity. The investors complained that the planned factory‘s daily output was too low and that the Flemish method should be employed. Türrschmiedt, however, proved via a number of lectures at the Polytechnical Society in Berlin, that German brick factories using the German soft-mud process were turning out higher tonnages than the Belgians, because Prussian bricks were larger and, by the way, of better quality.

3 Türrschmiedt as a speaker

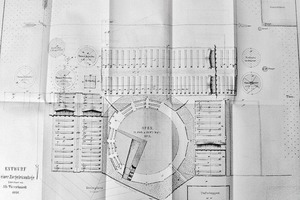

Keenly interested in the newly invented “ring oven“ (= annular kiln), Türrschmiedt travelled to Prague in the summer of 1860 to gather information on the performance of Friedrich Hoffmann‘s “sunken ring oven“. He spent several days watching the kiln‘s first trial firing.

Returning to Berlin, he presented a detailed report to the Polytechnical Society on February 21, 1861. He spoke not only on technical problems affecting the efficient combustion of various fuels, but also emphasized the special features and the principles of operation of Hoffmann-Licht annular kilns, which he lucidly explained in theoretical and practical terms. By then, Türrschmiedt was already well known in Berlin‘s technoscientific circles, as he had delivered and published papers on peat and brick fabrication as early as 1858/59. Indeed, in three other presentations, he spoke at length on “peat production“, beginning with the history of peat formation, the different types of peat, and their mouldability and combustion. His presentations bore witness to his profound knowledge of the sciences, his excellent powers of observation and his broad practical experience, all of which helped him become an all-round advisor to brickmakers.

4 The founding of „Deutscher Verein für die Fabrication von Ziegeln, Tohnwaaren, Kalk und Cement“

Albrecht Türrschmiedt reputedly urged Friedrich Hoffmann to join him in establishing the “Deutscher Verein für die Fabrication von Ziegeln, Tohnwaaren, Kalk und Cement” (German Association of Manufacturers of Bricks/Tiles, Pottery, Lime and Cement). At the society‘s inaugural meeting in 1865, Türrschmiedt was elected to the dual post of scribe and secretary by the assembled owners and proprietors of brick factories and annular kilns. In the initial membership roster, he was still listed as owning a brick factory. At that same inaugural meeting, he initiated a discussion regarding the meagre technical-educational background of brickyard owners and, in particular, of their master craftsmen and kiln operators – and made few new friends in doing so. He suggested that the Royal Prussian Brick Factory in Joachimstal on Lake Werbellin be placed under the management of Gottfried Menzel and used as a training facility and vestibule school. Unfortunately, nothing came of it. It was not until 1884 that the Ducal-Anhaltenian School of Architecture created a “brick“ department for training the brick and clay industry‘s first master craftsmen and engineers.

At the society‘s second general assembly in January of 1866, Friedrich Hoffmann was already praising Albrecht Türrschmiedt‘s outstanding performance in organizing the society‘s activities and, above all, in winning new members. Within a very short time, the society had already gained an international character. Within weeks, the membership roster counted Polish, Russian, Danish, Dutch, French, English and Austrian brickmakers representing all branches of the burnt siliceous construction materials industry. That forced him to come to grips with the theoretical and practical difficulties stemming from the introduction of annular kilns and auger extruders to the production of lime and cement.

It was in the mid-1860s that the drawbacks of using and operating annular kilns and auger presses the wrong way became more and more apparent. Building owners and contractors alike began to complain about poor body strength, frost damage, lamination and efflorescence. The society therefore decided to set up a laboratory for testing raw materials and finished products according to the then-available means and methods. They launched the project at Kesselstrasse 7 in Berlin, where the society was domiciled and Friedrich Hoffmann had his engineering firm. At the same time, they also realized that, in order to improve comparability, Germany needed a uniform set of standards for bricks and cement. Years before that, Türrschmiedt had already begun to investigate the subject of measurands for bricks and clinkers, including cement in all its various modifications and applications.

5 „Notizblatt des Deutschen Vereins für die Fabrication von Ziegeln, Tohnwaaren, Kalk und Cement“

Having assumed the duties of the association‘s scribe, Türrschmiedt was able to fully deploy his writing skills. He immediately began to publish and edit a newsletter entitled “Notizblatt des Deutschen Vereins für die Fabrication von Ziegeln, Tohnwaaren, Kalk und Cement”, which probably amounted to the world‘s first technical journal for ceramics, though it was only published for members. That, by the way, is the reason why only incomplete collections of that newsletter can now be found in but a very few scientific libraries. Those that do still exist amount to a treasure trove for technical historians. Most of the general assembly papers and contributions published in the newsletter stemmed from Türrschmiedt‘s own pen. They concerned things like differences between various loams and clays in terms of firing behaviour, the microstructures and properties of ceramic raw materials and how they should be taken into account for brickmaking, refractoriness, fuel consumption and much more.

At the inaugural meeting in January of 1865, he presented a rather protracted lecture on the character of Hoffmann’s “ring oven“ and its advantages in terms of effective firing of bricks, pottery, lime and cement. Most of the drawings appearing in the newsletter were drafted by Türrschmiedt himself.

6 The society‘s chemo-technical laboratory

In the years to follow, he studied the specific problems of firing in annular kiln operation, good firing programs and water-smoking methods, the introduction of a German standard format for bricks (presently known as Reichsformat, standing for 25 x 12 x 6.5 cm), compression testing of construction materials, the properties of diverse cements and hydraulic mortars, everyday problems of brick production, the effects of raw materials and firing program on the colour of bricks, ..., i.e., an abundance of topics, as even a quick glance at a list of pertinent literature would confirm. The society‘s emergent chemo-technical laboratory was a great help to him. for his plethoric endeavours, too. Later, the laboratory belonged to the ceramic trade periodical “Deutsche Töpfer- und Ziegler-Zeitung”. When pioneering ceramic scientist Dr. August Hermann Seger took over the laboratory at the request of Friedrich Hoffmann, he found a sound and solid foundation of chronicles and data records waiting for him. This allowed him to dispense with many preliminaries in developing his recommendations on kiln settings, water smoking and general firing considerations for annular kilns.

Alexius Riese, a Berlin-based architect, studied concrete residential construction on a trip to England. Motivated by his report, Türrschmiedt began to experiment with different types of cement, gravel, sand and ground brick waste for various concrete mixes at the laboratory. An article he published in a construction-sector gazette called “Deutsche Bauzeitung” at the time contained some initial suggestions on how to produce practical structural elements made of concrete. In 1872, drawing on those incipient findings, a first spate of concrete residential buildings were put up in Victoriastadt , Berlin, some of which are now heritage-protected. In 1873, a street in Victoriastadt was named Türrschmiedtstrasse, ostensibly in honour of his distinguished achievements as an architect in connection with the new suburb‘s planning, construction and supervision. There is no real proof available to back up this assertion, though, because Türrschmiedt was not an architect, nor did he help plan the streets and buildings in that part of Berlin. Moreover, Berliner Betonbau AG was not even established until 1872, the year after his death. While the stated birth data do match, there are any number of other reasons why this work cannot be attributed to Türrschmiedt.

7 „Deutsche Töpfer- und Ziegler-Zeitung“

1869, Türrschmiedt noticed that his “Notizblatt” newsletter did not suffice to reach all of the branch‘s interested professionals. After discussing the pros and cons of such a journal with the society‘s executive committee and failing to secure their undivided approval, he decided to strike out on his own and, in 1870, established a trade journal for German potters and brickmakers called “Deutsche Töpfer- und Ziegler-Zeitung”, which he forthwith published and edited. After Türrschmiedt died, Dr. August Hermann Seger became editor-in-chief, later to be succeeded by no less than Friedrich Hoffmann. While in 1924 the journal‘s name was changed to “Ziegelwelt”, or the “World of Bricks“, it remained in print until 1944.

Two weeks after taking a spa cure in Bad Burtscheid near Aachen, Albrecht Türrschmiedt unexpectedly died at work on October 14, 1871, of complications from a case of tonsillitis. His death was a major, irrecoverable loss for the society and the emerging brick and tile industry. As described by Dr. August Hermann Seger in an obituary in the “Deutsche Töpfer- und Ziegler-Zeitung” (as one of the numerous gratuitous services he rendered to the society and its members): “We have lost an ever assiduous, humorous, untiring teaching and mentor.“

At the next general assembly in January of 1872, it was agreed to establish a “Türrschmiedt Fund“ for helping young people get a good ceramic education and as a source of funding for relevant technical educational establishments. The society also resolved to erect Albrecht Türrschmiedt a worthy tombstone of Siegersdorf terracotta according to the plans of architect and future privy building councillor Friedrich Oskar Hossfeld (1848–1915) at the Protestant Cemetery Domfriedhof II at the corner of Müllerstrasse and Liverpooler Strasse in Berlin-Wedding.

8 Summary

Albrecht Türrschmiedt certainly was not a particularly creative or innovative brickmaker. He merely attempted to scientifically fathom, with the tools of his time, the physico-chemical and mineralogical context of ceramic building materials and, in particular, of brick production and to communicate his findings to the general public. It was he who introduced science to heavy clay technology. Hence, it was he who paved the way for Dr. August Hermann Seger, the founder of ceramic science.

Through his work, Albrecht Türrschmiedt endowed brickmakers with the theoretical armamentarium they needed for successfully coping with the winds of technological change, and he simultaneously established the foundations for curricula used by future brickmaking schools in Zerbst/Anhalt, Köthen/Anhalt, Lauban/Lower Silesia, Frankfurt/Oder, Sternberg/Mecklenburg, Lemgo and Lage/Lippe, Hermsdorf/Saxony, Zwickau/Saxony, Landshut/Bavaria and Apolda/Thuringia.

The world‘s first ceramic trade journal, Notizblatt des deutschen Vereins für die Fabrication von Ziegeln, Tohnwaaren, Kalk und Cement”, was definitely the result of his efforts and initiative.

Albrecht Türrschmiedt also took the lead in establishing a uniform German standard format for bricks (now called Reichsformat) in 1871 in cooperation with Friedrich Hoffmann and the German architects‘ association Verein Deutscher Architekten and, at the same time, established the basic principles for the specification of quality assurance test parameters.

In 1870, acting at his own risk, he established the “Deutsche Töpfer- und Ziegler-Zeitung” and, together with Friedrich Hoffmann, its affiliated chemo-technical laboratory. It was his work that led to Germany‘s first material test institute.

Acknowledgements

My heartfelt thanks to Ulrich Borgert, Dr. Wolfgang Müller, Dr. Lothar Schyia, Siegfried Müller and Wolfgang Orlamünder for their help in gathering information and pictorial material for this contribution.