Air energy meter – initial practical experience at a brickyard

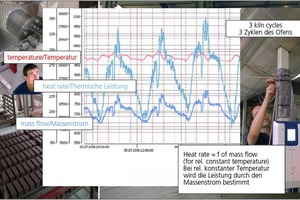

At brickworks, the medium “process air” transports large amounts of energy. Only in rare cases, however, are the airflow volumes and energy quantities continuously monitored. With a “Luftmeister” air energy meter, though, volume flow and heat rate can be quantified even in sophisticated process-air applications. The device also calculates the amount of energy passing through the air duct at any given time. Taking as an example the fully functional prototype installed at the Röben plant in Bannberscheid, this report elucidates the technology and recounts some initial field experience.

At a typical brickwork, the volumetric flows of diverse media need to be kept under surveillance. As a rule, this serves to facilitate the task of operational energy management. For any energy intensive industrial enterprise, this is not merely a hollow gesture but a matter of high cost relevance.

In most cases, this concerted array of logged data lacks one additional media flow: that of process air. Practically every conceivable brickyard has numerous large air ducts with diameters reaching 1 500 to 2 000 mm or more. Often, the conducted air displays temperatures on the order of 600 °C. Hence,...