The solid-solid recuperator – a forced-convection tunnel kiln for higher energy efficiency

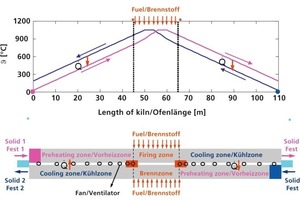

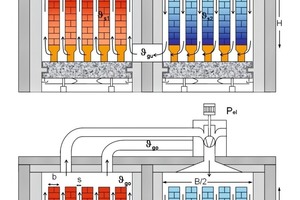

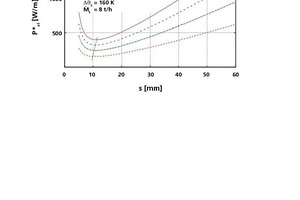

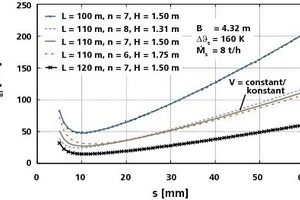

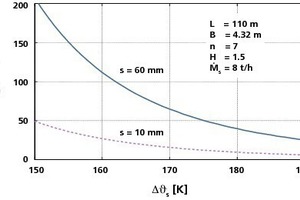

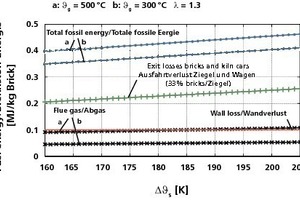

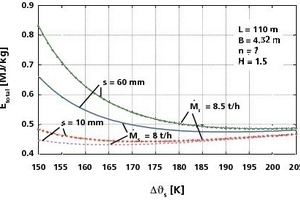

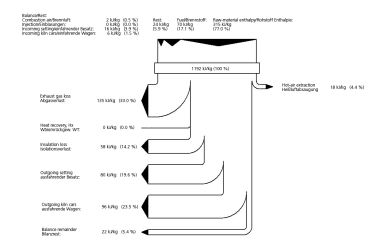

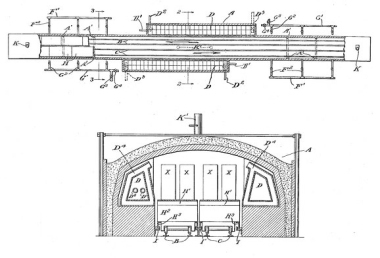

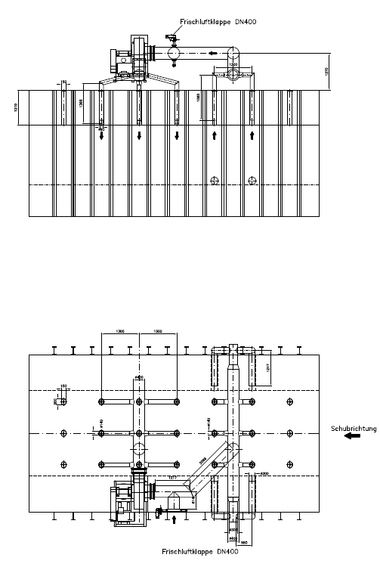

The counterflow tunnel kiln concept was refined and optimized. In this type of kiln, two lines of kiln cars run in opposite directions through the centre-split tunnel. Fans are used to keep the kiln atmosphere in circulation between the two sides of the tunnel. Hence, heat from the hot wares is transferred to the cold wares and vice versa. A mathematical model was generated for this solid-solid recuperation process. By means of the “Fluent” programme, the in-kiln flow in both directions, including burner-induced circulation, was simulated in three dimensions. The optimal set of operating conditions with regard to rapid heat transmission and low pressure loss was determined with allowance for minimized energy consumption in terms of flue, exit and wall losses and to fan power. Thanks to solid-solid recuperation, the energy consumption of this counterflow kiln was shown to be only about 40% as high as that of conventional tunnel kilns.