Do counterflow kilns hold the promise of an energy miracle? (Part 2)

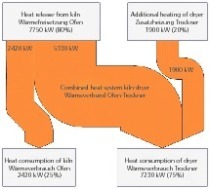

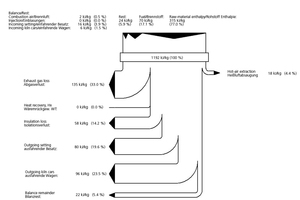

The theoretical principles governing the energy consumption of counterflow kilns are explained and compared with the actual performance data of existing counterflow kilns. In addition, the advantages and disadvantages of different types of counterflow kilns are discussed and their energy conservation potentials compared with the energy consumption of fast firing kilns.

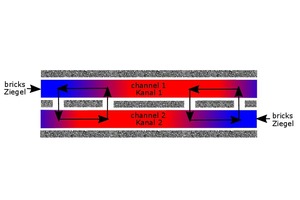

6 Counterflow kiln with forced circulation

In the interest of ongoing development for counterflow kilns, the transition to forced circulation with the aid of supplementary circulation fans (»4) would appear to be a logical solution [14, 15]. It would increase the rate of heat transfer and, consequently, reduce the required firing time. Accordingly, it would also reduce the specific insulation losses, the exit losses of the settings, kiln cars and kiln furniture, and the undercar cooling losses. Even conditions of flow approximating those of fast firing can be achieved with the help of...

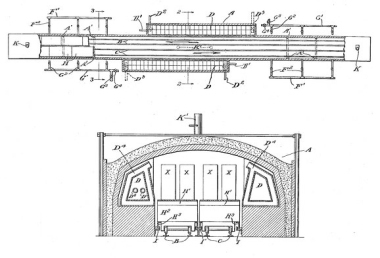

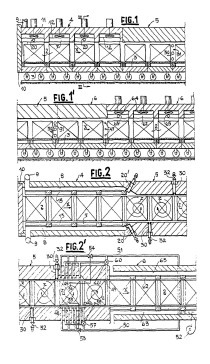

![»11 Sliced setting counterflow kiln by Rieger [12]](https://www.zi-online.info/imgs/1/3/5/1/7/7/5/tok_adf28e1df9a08f600168c6f3c66302fb/w300_h200_x421_y297_Zi2_Vogt_Bild_11-cf6868080941e26e.jpeg)