Benefits and boundary conditions of fast firing clay building products (Part 2)

This contribution is the last of four articles dealing with kiln settings in terms of pressure drop, flow distribution, convective heat transfer and optimal configuration, as well as with the boundary conditions and benefits of fast-firing kilns for clay building products [1-4]. Part 2 of this tripartite article describes the sizing of fast firing kilns.

4 Sizing of fast firing kilns

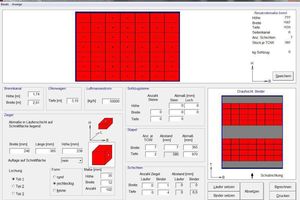

In this installment, an attempt is made to define the dimensions of future, thermally optimized fast firing kilns and their accoutrements according to present best-practice expertise and to the firing times postulated in item 2.

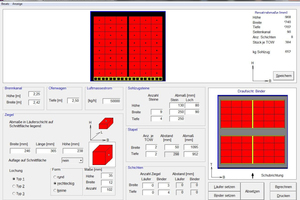

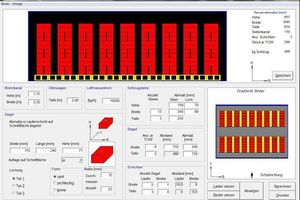

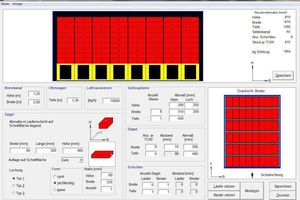

4.1 Sizing the firing channel

Nearly all clay product formats commonly employed in Europe and the USA can be fired in firing channels of similar size and dimensions by varying the number of hearths and/or the number of products per hearth. This is of particular importance for future fast firing kilns, which will be intended to handle as...

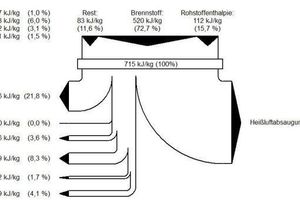

![»10 Sankey diagram of mean energy balance data of 44 examined backing brick tunnel kilns [51]](https://www.zi-online.info/imgs/1/2/4/2/0/7/3/tok_9dc323ce8ed5dcdacce636465a74e4d7/w300_h200_x400_y226_Bild_800_453-86c53aad52b7d078.jpg)