Benefits and boundary conditions of fast firing clay building products (Part 3)

This paper is the last of four articles dealing with kiln settings in terms of pressure drop, flow distribution, convective heat transfer and optimal configuration, as well as with the boundary conditions and benefits of fast firing kilns for clay building products [1-4]. Part 3 of this tripartite article describes the economic parameters of fast firing kilns.

5 Economic parameters of fast firing kilns

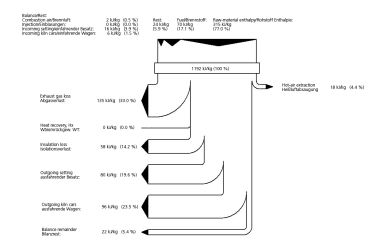

The cost of investment for a conventional tunnel kiln with a daily output of 500 t backing bricks presently comes to around € 4.7 mill., depending on the required accessory equipment. For a postulated gas price of 3.0 cents/kWh, and assuming the mean performance data mentioned in section 4.3 for the 44 backing brick kilns, the expenditures for fuel come to approx. € 2.2 mill. per year. On the other hand, the average such kiln contributes drying energy worth € 1.1 mill. via the combined energy system. The cost of fuel is the greatest single factor for...