Enviro kiln, an innovative new kiln concept with high energy saving potential

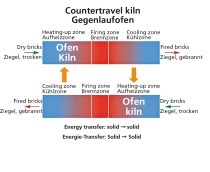

To drastically reduce the energy requirement for firing, Keller HCW is closely examining the principle of the countertravel kiln. Known research and principles have been studied intensively and the new “Enviro” countertravel kiln created based on redesign and modification. This kiln eliminates existing disadvantages and utilizes known advantages so that a completely new firing concept with a high energy saving potential is created. Extensive theoretical considerations supported, for example, by the “Fluent“ software preceded the studies for the redesign. On the basis of the resulting positive results, a test kiln (width 5 m, length 16 m and height 5 m) was built. Over several months, a team of employees has conducted numerous test firings with different products to review findings and obtain well-founded measurement data. Heat transfer based on convection and radiation has been determined and it has been verified whether energy transfer typical in countertravel kilns proceeds according to the solid-solid principle. Details on the “Enviro” kiln and sound hydraulic and thermodynamic findings are presented.

Dipl.-Ing. (FH) Rainer Hüsing, Keller HCW GmbH