The new Enviro kiln concept – countertravel kiln for the 21st century

Germany‘s energy transition is the embodiment of a fundamental change in how energy is supplied, and one almost automatically thinks of renewable energy sources in that connection. Energy efficiency, though, is just as important and of central significance. Why? Because energy that is not expended need not be generated. Keller HCW has therefore taken it upon itself to sustainably enhance the energy efficiency of its brickworks, hence reducing their energy-related CO2 emissions.

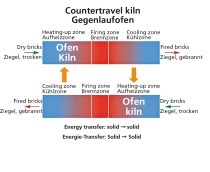

In order to drastically reduce the amount of energy needed for firing, Keller HCW has thoroughly revised the principle behind countertravel kilns. Known studies and fundamentals of the countertravel concept were intensively examined in preparation for creating the new “Enviro” countertravel kiln via redesign and modification. This kiln eliminates prior drawbacks and exploits known advantages to yield a completely new firing concept with high potential for conserving energy. Following extensive theoretical investigations conducted, for example, with the help of Fluent software, Keller HCW built a pilot kiln measuring 5 m wide by 16 m long and 5 m high. For months on end, a team of employees conducted numerous test firings with different products in order to ensure the integrity of current insight and findings while obtaining well-founded test data. Heat transition via convection and radiation was investigated, and the results show that the typical solid-solid mode of energy transfer in counter travel kilns actually works.

At the 2014 Würzburg Brick and Tile Training Course, the initial findings were presented to the German-speaking professional audience, including depiction of the major potential for reducing energy expenditures. Taking a typical roof tile plant as an example, this figures to more than 30 %. Now, the concept is being explained to an international professional audience, including presentation of the latest findings.

Ulrich Hagemann/Rainer Hüsing, Keller HCW GmbH,

Ibbenbüren-Laggenbeck, Germany