Influence of mineral additives on the drying and sintering behaviour of brick bodies, Part 2

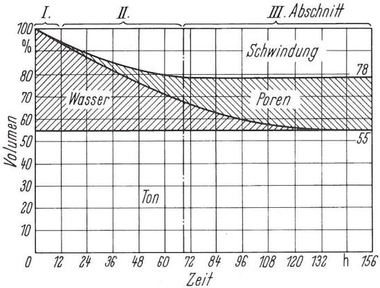

Drying is one of the most elementary processes in the manufacturing of ceramic products. With the removal of the water necessary for plastic shaping, the shaped product is transformed from a wet and plastic state into a dry state with a stable shape. As the evaporation of the water is an energy-consuming process, a reduction of the water needed for extrusion would therefore lead to an energy saving and, in addition, shorten the drying time. (Continuation of the technical paper from ZI 1/2022)

5. Characterization of the dried brick bodies

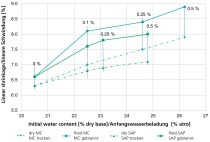

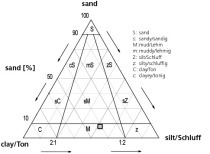

»Table 8 shows the shrinkage, packing density and bending strength of the dried brick bodies. The shrinkage of the basic bodies varies between 7.6 and 4.7 %. The shrinkage values average between 5.5 and 6.5 %. A correlation between the drying shrinkage and the mineralogy of the basic bodies and their particle size distribution cannot be identified. Only the coarse shale clay PK, which has lost part of its plasticity because of diagenetic compaction, exhibits correspondingly low drying shrinkage. Shrinkage is reduced considerably with the addition of the additives. This can be attributed to the lower moisture required for pressing or extrusion.

The removal of the water during drying leads on account of the capillary forces to volume shrinkage of the green body. The less water a body contains, the lower is its shrinkage. One exception is Body PK, for which drying shrinkage is minimally increased, which in the case of Mix PK 4 can probably be attributed to the lower percentage of coarse particles and increased moisture for pressing. For most of the modified brick bodies, the packing density of the dried green bodies increased considerably compared to the basic body. For Body HLZ 1, the packing density increased by up to 3.2 %. For Body HLZ 1 12, however, the packing density was lowered. The reason for this is the high increase in moisture for pressing compared to the basic body; the lower shrinkage could not compensate for the space required for the increased moisture (3.4 mass% water corresponds to 3.4 vol%). For Body HLZ 2, the packing density increased by a maximum of 2.2 % with simultaneous reduction of the drying shrinkage. Body PK 1 even registered an increase in the packing density by 4.5 %, as compared to the basic body, the drying shrinkage increased slightly. This confirms the original assumption that with the sole addition of Additive 1, the packing density could be increased the most efficiently (see »5).

But also for Body PK 4, the packing density increased significantly by 2.4 %, and that although the moisture for pressing was 1.8 % higher. While the drying shrinkage was higher, it does not, however, seem to suffice as an explanation. One possible explanation is that during extrusion, air is entrapped in the body because the vacuum pump is not strong enough, and therefore more or less air is always contained in the freshly extruded green body, which always has an effect on the packing density. In the case of Body VMZ, the packing density increased by a maximum of 3.8 % with a slightly reduced drying shrinkage. For Body DZ 1, it increased by a maximum of 2.7 % with slightly reduced drying shrinkage at the same time. Body DZ 2 presents an exception to the results so far as the packing density remained unchanged. The drying shrinkage, too, is virtually identical, and even for the moisture for pressing, there was only a slight decrease. It is unclear why this body is an exception. Generally, however, there is a good correlation of the packing density with the pressing moisture, i.e. the bodies in which the pressing moisture has been reduced by the additives also show higher packing density. The measured packing densities differ quite considerably from those calculated and listed in »Table 4. This deviation results from the fact that the program does not take into account, for example, any agglomeration of the particles and, for the purpose of simplification, only round particles were simulated. Moreover, the mineralogical composition and the associated shrinkage processes have no influence on the simulation.

With regard to the bending strength of the individual brick bodies, it is noticeable hat the smectite-containing basic bodies (HLZ 1, HLZ 2, DZ 2) exhibit the highest bending strength. Here too, a clear difference can therefore be determined between the smectite-containing and smectite-free bodies. The bending strength of the modified bodies is lower for all clays than that of the basic body. For the basic bodies with particularly high bending strength, the decrease is somewhat sharper. Only in the case of Body PK can no negative effect of the additives be determined. However, this body also exhibits the lowest bending strength. The reduction in the bending strength can ultimately be attributed to the reduction of the clay mineral content as the clay minerals endow the green body with cohesion based on electrostatic interactions. However, the smectite content of many additives has no visibly positive influence on the bending strength. The higher packing density of the modified bodies does not improve the strength either as no correlation can be detected between the bending strength and the packing density within the individual bodies. With regard to the dry bending strength, generally negative effects of the additives are shown.

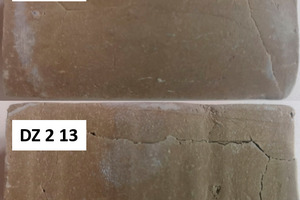

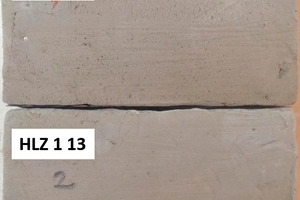

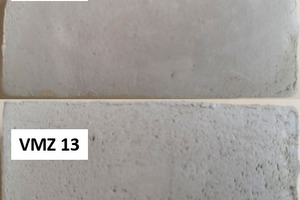

The reduced drying shrinkage can be rated as positive as the maximum stresses that are imposed during drying are reduced, as a result of which the probability of drying cracks is lowered. »7 shows the influence of additives on the drying crack sensitivity based on Bodies DZ 2, HLZ and VMZ. In this experiment, test specimens were dried in a climatic cabinet specially designed for this purpose, under defined conditions (flow velocity: 2 m/s, temperature: 80 °C, relative humidity: approx. 3 %). For Body DZ 2, clear drying cracks were formed both in the basic body as well as in all mixes. Here the additives did not have any effects on the drying shrinkage. A similar result was shown by Body HLZ 2. Here, all the test specimens also exhibited cracks although the drying shrinkage of the modified bodies was slightly lower. The bodies with tendentially low dry shrinkage (PK, VMZ, DZ 1) exhibited no drying cracks in the test. Body HLZ 1 ranges between these two extremes as the basic body exhibited clear cracks, whereas the modified bodies were free of cracks. This is probably down to the much reduced drying shrinkage compared to the basic body. The results of the test can be used to evidence that the crack tendency of the brick bodies can be reduced with mineral additives.

Both the drying shrinkage and the moisture conductivity have an influence on the crack formation tendency. The drying shrinkage should be as low as possible, because a green body that exhibits no drying shrinkage would, irrespective of its moisture conductivity, never suffer cracks as no differences in shrinkage can occur. The moisture conductivity, on the other hand, should be as high as possible as a green body with infinite moisture conductivity would never crack either as no moisture gradients and therefore differences in shrinkage can develop inside the green body. To avoid crack formation, the reduction in drying shrinkage is, however, of greater importance than the increase in moisture conductivity, as stresses can only be generated by differences within the green body, and the lower the shrinkage is, the lower the maximum stress that can develop. Moreover, in Body DZ 2, while the moisture conductivity was increased substantially by the additives, this did not prevent the formation of drying cracks.

Pressing moisture, moisture conductivity, water vapour diffusion resistance factor, drying shrinkage and dry density were used as input parameters for the ZiTro program, with which the energy and time required to dry the brick bodies to a residual moisture content of 2 % were calculated. In the calculation for Bodies HLZ 1 and 2 and DZ 1 und 2, a maximum thickness of the green bodies of 20 mm was assumed, while for Bodies PK and VMZ, 70 mm was taken as the maximum thickness. In »Table 9, the times required for the two drying stages and the required drying energy calculated with the program are listed. It is noted that only Bodies PK and VMZ undergo the second drying stage for a long time, which is attributed to the greater thickness of the specimens; this leads to an increasing influence of the slow water vapour diffusion. In addition, as a result of this, the first drying stage is shorter than for the other four bodies and the energy required much higher. Relative to 1 kg water, the four bodies HLZ 1 and 2 and DZ 1 and 2 show an identical energy requirement. If, however, the energy is related to the pressing moisture of 1 kg dry clay, the modified bodies show a much lower energy requirement as the moisture they require for pressing/extrusion is lower, and accordingly less water must be evaporated. The time for the first drying stage also correlates very well with the pressing moisture, that is the lower the moisture required for pressing is, the shorter time this stage takes. The reduction of the pressing moisture therefore has an extremely positive effect on the required drying energy and the drying time. For Body DZ 1, the energy required and drying time could be reduced by almost 30 % with the additives.

6. Characterization of the fired brick bodies

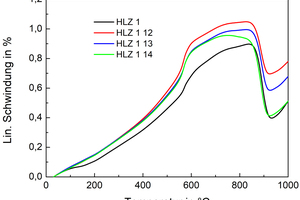

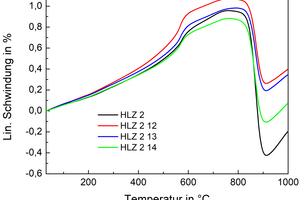

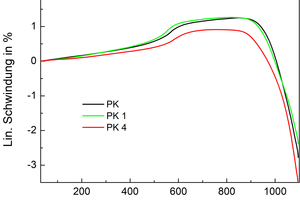

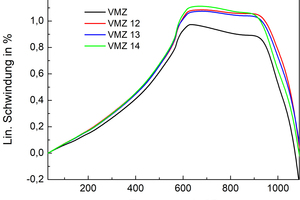

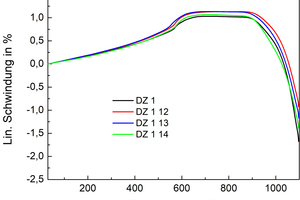

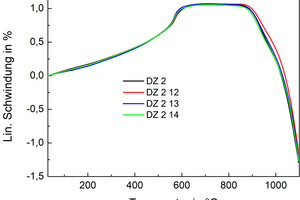

»8 shows the dilatometer curves of the individual brick bodies. The shape of the curve during preheating is similar for all bodies. Thermal expansion is approximately linear with the temperature up to quartz inversion at 573 °C, which is associated with a sharp increase in volume. Above the quartz inversion, the curve of the two bodies HLZ 1 and HLZ 2 clearly differs from that of the other masses. The reason for this is the different content of kaolinite and illite. The backing brick masses are characterised by illites and illitic masses expand in the range between 600 and 900 °C, whereas kaolinitic masses shrink in this range (see mass VMZ). The masses DZ 1 and DZ 2 contain similar amounts of illite and kaolinite, which is why there is no change in length in this temperature range (Hlan und Štubna 2020). At around 900 °C, there is a sharp increase in volume occurs in the backing brick masses, which is probably caused by the formation of gehlenite, which is formed out of a reaction between the deacidified lime and the dehydroxylated clay minerals. In the other bodies, shrinkage continues steadily with increasing temperature.

The sintering temperatures, which are specified in »Table 11, were determined by fitting a tangent at an angle of 45° to the measurement curve in the region of the start of sintering. Between the basic bodies and the modified bodies, there are no big differences at the onset of sintering. The bodies that contain Additive 4 sinter somewhat earlier than the two other mixes and the basic body. This is probably caused by the high content of clay minerals and fluxes like calcium and especially magnesium compared with the other additives.

The specimens of the individual bodies were fired under the conditions specified in »Table 10. The firing loss is much lower in the modified bodies HLZ 1 and HLZ 2 than for the basic body. This is caused by the exchange of the high-carbonate clay with low-carbonate additives. This reduces the carbonate content of the modified bodies and accordingly the loss on ignition, which is caused by the separation of the CO2. The use of low-carbonate raw materials is therefore also an efficient method for the reduction of the process-related CO2 emissions in backing bricks. The clay minerals also contribute to the firing loss because of the removal of the crystal water. The different losses on ignition of the additives also become visible in the brick bodies, i.e. of the modified bodies, the bodies with Additive 4 exhibit the highest firing losses and the bodies with Additive 2 the lowest.

The firing shrinkage of the modified bodies lies below that of the basic bodies. One reason for this is the higher packing density as the shrinkage is associated with a reduction in volume, and a volume shrinks all the less, the denser it is already packed. Bodies HLZ 1 and HLZ 2 show hardly any shrinkage, as the formation of a new mineral compensates for this. For Body PK. the Mix PK 1 shrinks less than the basic body, whereas Mix PK 4 shows higher shrinkage than the basic body although it also had a higher packing density. Here, the sintering-promoting effect of the additive at high temperatures is evident. However, this effect is only evident in the case of Body PK, which generally has the highest shrinkage of all the basic bodies. The reason for this is the high potassium content of the clay, which effects the formation of a melt phase. This development is further intensified by Additive 4. Bodies VMZ and DZ 1 exhibit a much lower potassium content and therefore do not shrink as strongly despite being fired at the same temperature. Here, the shrinkage of these three basic bodies correlates with the potassium content, that means PK > DZ 1 > VMZ. The modified bodies of Clay VMZ show, apart from Mix VMZ 14, slightly lower firing shrinkage than the basic body. This could be expected on account of the higher packing density after drying. In the case of Body DZ 1 on the other hand, the shrinkage of the mixes is much lower than that of the basic body, although the packing density after drying was much higher only in the case of Mix DZ 1 12. The firing shrinkage of the modified bodies of Clay DZ 2 is also lower than that of the basic body despite the same packing density of the dry green bodies.

The packing density in the fired state is ultimately the result of the packing density in dried state, the firing loss and the firing shrinkage, that is with comparable firing loss, dry green bodies with high packing density and high firing shrinkage also show high packing density after firing and vice versa. The influence of the firing loss is shown in Bodies HLZ 1 and HLZ 2. After firing, these show an even a lower packing density than in their dried state. This is caused by the high carbonate content as the cavity volume formed as a result of the decomposition of the carbonate cannot be compensated for by the firing shrinkage. On account of the lower carbonate content, the packing density of the fired modified brick bodies is much higher than that of the basic body. Body PK 1 has a lower packing density than the basic body, whereas Body PK 4 possesses higher packing density, and that although the packing density of Body PK 1 after drying was higher than in Body PK 4. This circumstance clearly indicates the importance of the firing shrinkage and therefore the influence of the sintering activity of the additives on the packing density of the fired body. For the packing density in the dried state, the particle size of the additive is crucial, for the packing density in the fired state, its sintering activity matters most. In the mixes of Body VMZ, the ranking of the packing density corresponds to that in the dry state. On account of the different firing shrinkage, only the order magnitude has changed. Body VMZ 12 shows a somewhat lower and Body VMZ 13 a somewhat higher packing density. Only the packing density of Mix VMZ 14 is significantly increased compared to the base body. In the case of DZ 1, all mixes have a much reduced packing density compared to the basic body. This is caused by the much lower firing shrinkage. The same applies for Body DZ 2, although here the difference is not quite as large as the packing density of the dried bodies is almost the same and the firing shrinkage was only slightly lower.

The bending strength of the fired, modified bodies is much lower than that of the basic bodies (see »Table 11). Here, the missing sintering activity of the additives is evident. However, it should be taken into consideration that 20 % of the crushed sand and only 10 % of the filter dust were added and the crushed sand exhibits, on account of its high quartz content, lower sintering activity than the filter dusts, which exhibit high contents of phyllosilicates and feldspars. These contain much more fluxes (alkalis and earth alkalis), which effect the formation of a strength-increasing melt phase. This difference is seen very clearly in Body PK. The mix with 30 % of the low-flux crushed sand has an extremely low bending strength, whereas the mix with 30 % of the high-flux Additive 4 demonstrates just as high strength as the basic body. However, here, the firing temperature also plays a part as all the more melt phase is formed, the higher the firing temperature is.

The influence of the flux becomes clear on examination of the lime-free basic bodies, which, apart from Body DZ 2, were fired at 1100 °C (see »Table 12). Body PK has the highest flux content and, in combination with the lowest packing density, very high firing shrinkage results, which leads to the highest compaction and therefore to the highest bending strength. Body DZ 1 shows the second-highest packing density. This is caused by a high flux content and the second highest firing shrinkage starting from the highest packing density of all dried bodies. Body VMZ contains the lowest quantity of flux and has low firing shrinkage. The packing density of the fired body is lower than in the two previous bodies, which results in a lower bending strength. Despite having the second highest flux content, Body DZ 2 exhibits the lowest firing shrinkage and packing density, which can probably be attributed to the 50 °C-lower firing temperature. The bending strength is nevertheless only insignificantly lower than in Body VMZ.

The two Bodies HLZ 1 and HLZ 2 have a much lower firing temperature and, despite much lower packing density, comparatively high strength. This can be very probably attributed to the new mineral formation, which can be seen in the dilatometer diagram (see »8). This mineral (probably gehlenite) is formed by the reaction of the calcium oxide formed as a result of decomposition of the calcite with the decomposition products of the clay minerals. The reaction is associated with volume expansion, which turns out stronger in the case of Body HLZ 2 as the body contains more calcite. A closer look at the two diagrams reveals that this expansion is not the same for all bodies and the differences are reflected even in the bending strength (see »Table 13). Probably because of the partial substitution of the high-lime base body with the low-lime additive, the formation of gehlenite is decreased as less calcium is available. This is expressed in lower expansion, and also in lower strength. This underpins the assumption that Additives 3 and 4 have a much higher calcium content than Additive 2 and therefore can form more gehlenite. The strength of Bodies HLZ 1 and HLZ 2 is therefore based to a certain extent on the formation of a crystal phase at low temperature, whereas the other four bodies are endowed with their strength owing to the formation of a glassy phase at relatively high temperatures.

7. Summary

With the use of mineral additives, it is possible to selectively increase the packing density of brick bodies with positive effects on drying shrinkage, drying time and drying energy. The additives must, however, meet certain preconditions. Seen over the entire project, Body PK demonstrates very well the salient aspects of this research project:

With the addition of the coarse crushed sand, the moisture required for extrusion could be reduced, whereas the addition of fine filter dust even increased this. It is shown, therefore, that the use of coarse additives increases the packing density the most efficiently.

The missing sintering activity of the crushed sand leads, however, to a poor compaction and therefore a lower strength compared with the filter dust.

The additives should therefore exhibit the following properties:

The quartz content should be as low as possible because quartz reduces sintering activity. Instead the content of phyllosilicates and low-melting minerals should be high.

The ideal PSD of an additive for increasing the packing density should be very narrow with a D50 in the region of around 300 µm. Much finer additives are less efficient for increasing packing density as the PSD of clay and additive increasingly overlaps. Much coarser additives lead to a sand-like body and sintering activity decreases.

For lime-containing backing bricks, the additives should contain as much calcium as possible to enable the formation of gehlenite, which endows the bodies with strength. However, coarse additives are disadvantageous as they only exhibit a small surface area, whereas the formation of gehlenite is all the stronger, the larger the surface area of the additive is.

The results are based on the IGF project 20623 N of the Research Association of the Brick and Tile Industry, which was funded by the Federal Ministry of Economics and Climate Protection via the AiF as part of the programme for the promotion of joint industrial research (IGF) on the basis of a resolution of the German Bundestag. The final report can be requested from the Research Association.