1 Context and formulation of problem

Employed as organic additives, paper sludge and sawdust serve to induce the formation of pores and voids in vertically perforated clay bricks. For reasons of energy economy, the addition of such porosification agents must be limited in volume. Paper sludge and sawdust are wood derivatives. The swelling behaviour of wood is pronouncedly directional and can amount to as much as 5%. As it swells, the wood absorbs some 30 mass % of its own weight in water. To the extent that swellability can be of use in brick production, the porosity should be enhanced without increasing the fuel value.

2 Implementation

The effects of swelling porosification agents on the material properties were studied on extruded test specimens. This involved adding organic porosification agents with defined water contents to clays intended for vertically perforated clay bricks. The specific addition, as referred to the total dry solids, was held constant in order to exclude any loss-on-ignition influence on the porosity. Both the paper sludge and the sawdust were first dried at 40° C and then, in part, soaked in water until supersaturated.

3 Findings

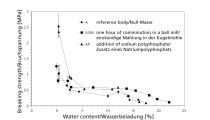

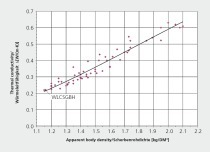

The results show quite clearly that elevated equilibrium moisture contents (fibre saturation point) of the various paper sludges drastically reduce both the porosity and, hence, the thermal conductivity. Moreover, the porosifying effect differs from clay to clay. Water contents exceeding the fibre saturation point are added between the fibres, i.e., in the filler, where, due to enhanced drying shrinkage, they cause no reduction in apparent density. The same phenomenon is also observed for other swelling materials. In general, bodies containing swollen additives (as compared to dry additions) display higher density coupled with lower compressive strength. The swollen additive displaces part of the clay minerals in the green brick. The clay mineral density is lower than that of water. Hence, the addition of swollen porosification agents to the mixture makes the fresh apparent density appear comparatively low. The weight and structure of the clay in the green brick reduce the shrinkage. The swollen additives enlarge the potential pore volume, but linear dry shrinkage compensates those pore/void spaces. Artificial enhancement of the water content is not expedient for bodies containing traditional porosification agents, because it corrupts their properties, if only minimally, and increases their drying energy requirement.

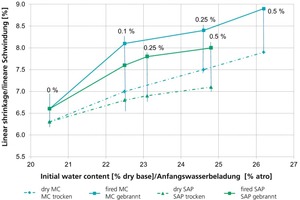

Superabsorbers (SAP) and methyl cellulose (MC) also were investigated (cf. »1). For constant plasticities according to Pfefferkorn, these highly swelling additives increase the water content. Assuming equal additions, methyl cellulose increases both the water content and the linear drying and firing shrinkage more than does the superabsorber. In both cases, however, drying shrinkage is so high, that the ceramic body density increases.

Interestingly, the use of methyl cellulose increases the body‘s plasticity and therefore makes it much easier to handle and extrude excessively moist clay. Methyl cellulose also has a dispersing effect, thus enabling untextured extrusion despite high plasticity. If, for example, a body containing 0.25% methyl cellulose is extruded at Pfefferkorn 28, its initial water content drops to 22.7% dry base, and its linear shrinkage decreases to 5.9%. The body‘s shrinkage is therefore lower than that of the reference body.

This project of the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ) was funded under the project number AiF 16424 N by the BMWi through the German Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF). It was implemented by the Brick Research Institute Essen Regd (IZF). The 95-page final report is available from the Research Alliance of the Clay Brick and Tile Industry Regd in Berlin.