Enhancement of the hydrostatic capillary tension in wet brick green bodies for a reduced susceptibility to cracking during drying

Research project conducted by: Research Alliance of the Brick and Tile Industry reg'd (FGZ)

Project number

AiF 15868 N

Promoted by

BMWi through the Cologne-based Arbeitsgemeinschaft industrieller Forschungsvereinigungen "Otto von Guericke" e.V. (AiF)

Implemented by

Institut für Ziegelforschung Essen e.V. (IZF)

Project manager

Dipl.-Ing. Ingo Hofmann

1 Context and problem statement

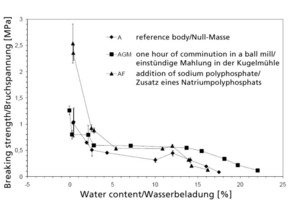

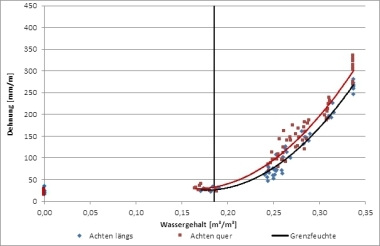

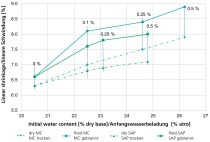

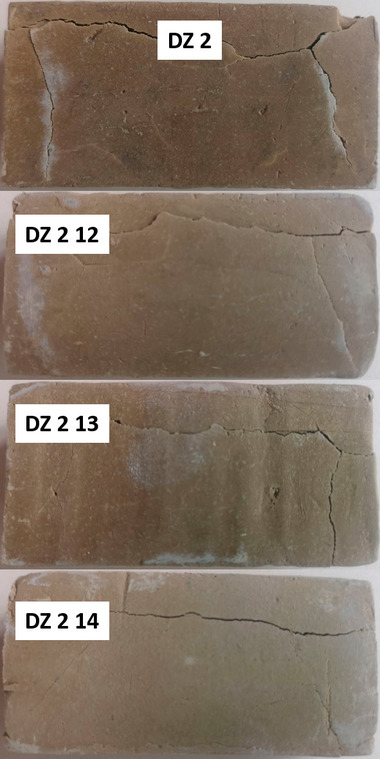

At first, shrinkage compensates for the loss of water associated with drying. However, as the water content diminishes, the coefficient of moisture conductivity also declines. If the drying rate is kept constant, the moisture gradient and, hence, the shrinkage gradient increase. When the tensile yield point is exceeded, tensile...