Energy-conserving method for obtaining

highly porous structures in brick clay

Reserch project conducted by the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ)Project numberAiF 16568 NProject funded byBMWi through the Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF)Implemented by

Brick Research Institute Essen

Regd (IZF)Project managerDr.-Ing. Anne Tretau

Context and formulation of problem

Vertically perforated clay bricks are highly porosity enhanced wall-building masonry units displaying low thermal conductivity. The thermal conductivity of stuffed bricks is the results of a combination of heat transmission through the body matrix and through the insulating material in the stuffed perforations. In unstuffed bricks, thermal radiation from web to web across the perforation is also of relevance. Hence, the essential quantifying factor for the thermal conductivity of masonry bricks is the thermal conductivity of the body. Brick bodies are rendered less dense by pores that form when organic porosifiers burn off, and by the use of highly porous lightweight inorganic materials. There are limits to the use of opening materials, however, because excessive amounts could make it difficult to reliably control the tunnel kiln.

Objective

Alternative porosification agents are investigated, because conventional porosification agents are becoming foreseeably scarce.

Experimental procedure

Metallic aluminium and surfactant foam are added to different clay bodies for the purpose of determining their effects on thermal conductivity.

Findings

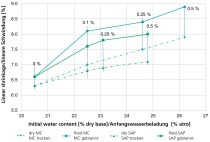

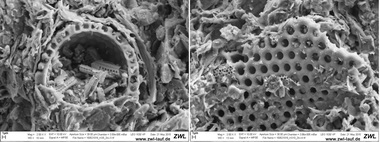

Metallic aluminium serves particularly well as a porosification agent. Theoretically, 0.15 mass % aluminium yields 70 vol.% pores. In practice, of course, a major share of the pores are destroyed by the intrinsic weight of the green body and the pressure of extrusion. Those remaining, however, are considerably finer and, hence, more stable than in the surfactant foam. Enhancing the porosity of perforated bricks with aluminium alone is not expedient, though. The addition of a light, extensively round stabilizing grain is advisable.

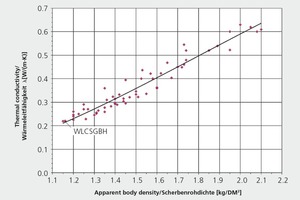

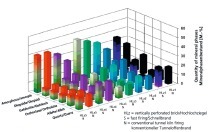

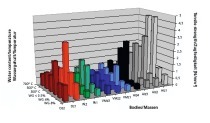

The exemplified mixture WLCSGBH was extruded to Pfefferkorn 13. The stiffening reaction of calcium hydroxide renders the green body inherently stable (shapre retaining). After 15 min., pore formation due to the presence of metallic aluminium is complete. Gas evolution also must be brought to completion prior to extrusion. Otherwise, “pimples” will form at the surface. The fresh apparent density is so high, that the intrinsic weight of the clay destroys 40 % of the pores. Increasing the initial water load heightens drying shrinkage, and the extruded compound no longer retains its shape. In »1, the subject composition is shown in relation to the other test findings. The apparent body density values range near the lower end of those displayed by commonplace vertically perforated clay bricks. The apparent body density also influences the compressive strength. Due to the low apparent density, the compressive strength amounts only 4.3 MPa. The diagram clearly illustrates how significantly the composition influences the body‘s strength. In the composition WLCSGBH, lime addition had a strength-reducing effect.

The thermal conductivity values are computed by way of a mathematical model that describes the body as a two-pore-size model, according to which a large cubic pore is surrounded by small cubic pores. The internal resistance of the pores constitutes a “parallel connection” between the resistances to radiative, convective and conductive heat transmission within the enclosed gas volume. The theoretical thermal conductivity values are in close agreement with those determined according to the heating-wire method. The thermal conductivity and porosity of the clay building material are determining factors.

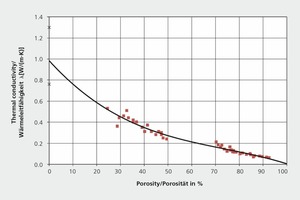

The thermal conductivity of the solid body was determined by plotting the measured thermal conductivity values of the individual bricks and extrapolating a trend line starting at 0% porosity (see »2). This yielded a value of 0.98 W/(mK). That value is situated between the thermal conductivity of crystalline SiO2 (1.3 W/(mK)) and that of glass (0.78 W/(mK)).

Due to the numerous factors affecting porosity enhancement, no relationship can be established between body composition and the resultant apparent density. Low fresh apparent densities and high viscosities reduce the degree of foam destruction, but they do not necessarily lead to low fresh apparent densities. Drying shrinkage has a major impact on porosity.

This project of the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ) was implemented by Brick Research Institute Essen Regd (IZF). The IGF project 16568 N of Research Association of the Brick and Tile Industry Regd (FGZ) was funded via AiF by the German Federal Ministry of Economics and Technology within the framework of the Programme for the Promotion of Cooperative Industrial Research (IGF) on the basis of a decision by the German Bundestag. The 101-page final report is available from the Research Alliance of the Clay Brick and Tile Industry Regd (FGZ) in Berlin.