Assessing the suitability of selected wastes as additives to clay bodies in brick manufacture

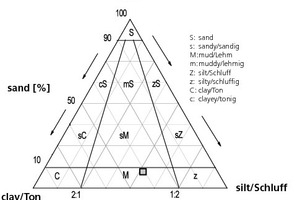

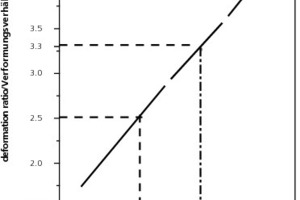

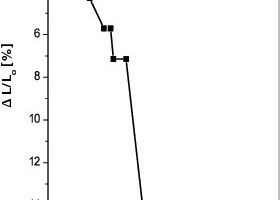

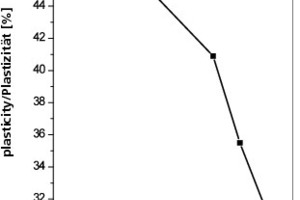

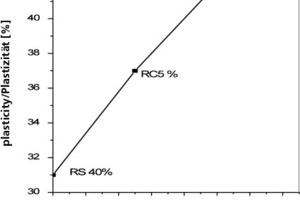

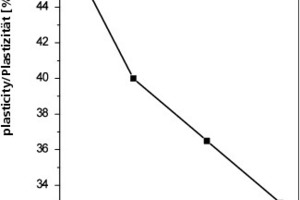

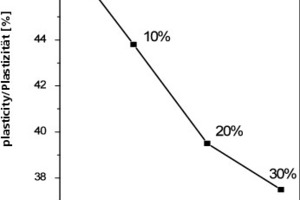

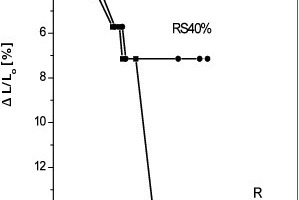

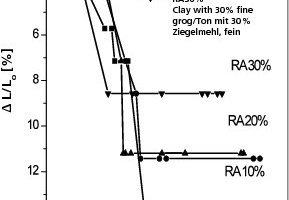

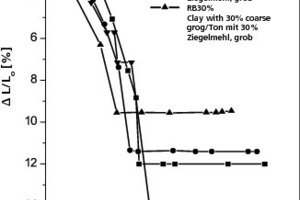

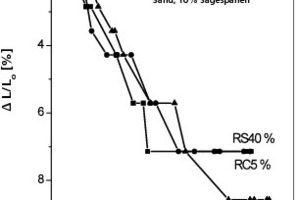

The article describes the assessment and optimization of a clay from a new quarry owned by an Egyptian company as a raw material for the manufacture of clay bricks. Various tests were conducted on representative samples of the raw clay to determine its particle size distribution, chemical composition, plasticity as well as its drying and firing behaviour. In addition, the effect of some additives (sand, reject fired bricks, that is grog, and sawdust) on the plasticity, drying and firing behaviour of the clay bodies was investigated.