Modern raw materials for the clay brick and tile industry

Part 4: White rock fillers from Henau Quarry

The raw materials sector is currently characterized by far-reaching transformation and the collapse of supply chains. The clay brick and roofing tile industry is increasingly impacted by this. The expeditious implementation of new raw materials concepts appears more important than ever.

1 Geological background and location

At Henau Quarry, Taunus quartzite from the Lower Devonian is extracted and processed to high-quality aggregates and high-grade chippings. The material is used amongst other things as brightener in road surfaces and runways at airports. The equipment for crushing, sizing and dedusting was completely revamped in the year 2020 (»1). With the new processing equipment, rock fillers with different particle size distribution are now produced. The quarry is operated by Nahe-Hunsrück Baustoffe GmbH & Co. KG, a subsidiary of Basalt-Actien-Gesellschaft. Sales for the ceramics and steel industries are managed by Dr. Krakow Rohstoffe GmbH.

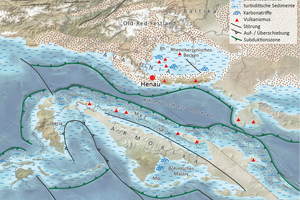

With regard to its geology, the quarry forms part of the Hunsrück-Taunus range, which represents the southern fringe of the Rhenish Slate Mountains. The region is therefore part of the Laurussia supercontinent, specifically the Avalonia microplate (»2). The stratigraphic sequences opened up at the quarry from the Middle-Lower Devonian (Siegenian/Pragian), which were formed here around 410 – 405 million years ago as a result of sedimentation in the Rhenohercynian Back-Arc basin. In the course of diagenesis, the up to 1 000-m-thick coastal sand were first buried geologically and transformed into silicified sandstones/quartzites. As part of the Variscan Orogeny, in the Carboniferous the strata were exhumed and tectonically deformed/overthrust (»3).

2 Mineralogical and chemical composition

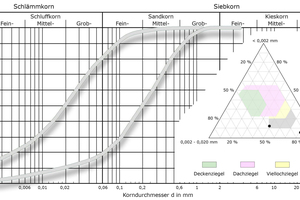

The rock fillers from Henau cover a particle size spectrum from the clay grain range to coarse sand. For the fine rock filler, the maximum particle sizes lie in the silt range from d = 0.002 – 0.06 mm. In the coarse rock filler, the maximum particle sizes are in the fine to medium sand range from d = 0.06 – 0.6 mm (»4). Differences in the particle size distribution are reflected as expected also in the mineralogical and chemical composition of the rock fillers.

When it comes to their mineralogy, the rock fillers from Henau have a comparatively simple composition. According to X-ray diffractometric analysis, they consist of a mix of tectosilicates/quartz and phyllosilicates, the phyllosilicate content varying between 18 – 33 mass % depending on the filler type. Dominant clay mineral is illite/mica, which can be classified as an innercrystalline non-swelling three-layer silicate. Disordered kaolinite is present as an auxiliary mineral. As expected, on account of the diagenetic burial, expansive clay minerals are absent (»Table 1).

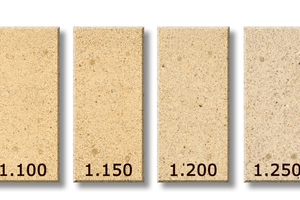

In chemical terms, silicon and aluminium dominate clearly before all other elements. Alkaline and alkaline earth fluxes are largely absent, only in the fine rock filler is potassium is present in a significant amount owing to the considerable content of illite/mica. Very low iron content between 0.52 – 0.77 mass % mean light fired colours can be expected. The absence of carbonates and only minimal contents of organic carbon cause hardly measurable CO2 emissions between < 0.04 – 0.22 mass % (»Table 2). For comparison: Conventional brick clays and clay marl reach values up to 15.0 mass % CO2.

3 Ceramics-related characteristics

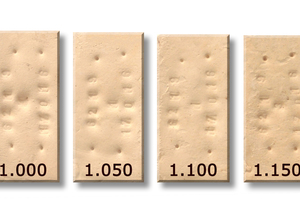

The fine-grained rock filler can be supplied dry in a silo truck or wetted in a tipping semi-trailer. In the wetted state, the moisture content ranges between 5 – 8 mass %. In brick plants, the fillers do not have to be comminuted further, but only homogeneously mixed with the other body components. The weakly plastic rock fillers are used as a drying agent and grog, predominantly in light-and buff-firing bodies. The coarse rock filler contributes to stabilizing the granular structure in the sand grain range. Both fillers exhibit light firing colours and high refractoriness (»7).

4 Volume availability and final remarks

At Henau Quarry, around 11 000 tpa of the coarse and 4 000 tpa fine rock filler are currently available. However, the energy transition is already casting dark shadows. To an exponentially increasing degree, rock fillers are now being used outside ceramics, for example in the steel industry, in agriculture and forestry or as a fly ash substitute. Interested brick plants should therefore secure their required annual quotas promptly.

Ber. Dt. Keram. Ges., 31, S. 337–343.