Modern raw materials for the clay brick and tile industry –Part 3: Mica schist from the andalusite-mica rock quarry in Schelmberg

The use of secondary resources is a current trend and gaining increasing acceptance. In the meantime, in clay brick and roofing tile plants, too. This report presents a contact-metamorphically overprinted mineral filler with the properties of low-carbon and finely prepared argillaceous schist.

1. Geological background and location

Andalusite-mica rocks are contact-metamorphic texture-free rocks. Mineralogically, they consist mainly of mica, quartz and feldspar. The metamorphic mineral andalusite is also present as an accessory mineral. Andalusite-mica rocks are formed when acidic magmatic melts intrude into clay schist layer sequences.

At Schelmberg quarry near Kirchberg, rock grades have been produced from andalusite-mica rock since 1999 and processed to high-grade aggregates for the asphalt and concrete industry as well as for road construction (»1). When the filler is removed from the rock grades, a fine-grained secondary resource is formed, which exhibits the properties of a finely prepared clay schist. The quarry is operated by Steinbruch Schelmberg GmbH & Co. KG, a subsidiary of Hartsteinwerke Vogtland GmbH & Co. KG. The quarry, located near the A72 motorway, has an approved extraction area of 7.3 hectares, which can be extended to 27.3 hectares.

Geologically, the quarry is in the Saxothuringian zone of the Variscan orogeny, specifically in the area of the around 1.5-km-wide contact zone of the Kirchberg granite plutons. At the turn from the Lower Carboniferous to the Upper Carboniferous, around 325 to 318 million years ago, the Kirchberg granite intruded into Ordovician phyllites and Cambrian clay schist (»2).

2. Mineralogical and chemical composition

As expected, the mineral content of the separated fines of the andalusite-mica rock reflects the mineralogical composition of the parent rock only relictically. It is affected particularly by the mechanical processing and filler removal. Primarily the low-gravity and fine-grained components are concentrated in the separated mica schist, which contains fewer heavy minerals in comparison with the coarse rock grades.

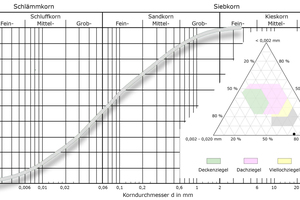

Schelmberg mica schist has a grain structure dominated by sand and silt grain, without any appreciable content of very fine grains. The screen oversize d > 63 µm averages 54 mass%. The particle size distribution of the material therefore corresponds to a sand-silt mix in accordance with DIN 4022 (»3). One special feature of the mica schist is that most of the grains are rock fragments of tightly interlocked mineral aggregates with random microstructure. The term sand is therefore not synonymous with the mineral quartz, but should be understood only in the sense of a grain size interval from 0.06 mm to 2.0 mm.

Mineralogically, the material is characterized by a significant content of phyllosilicates (71 mass%), specifically potassium- and aluminium-rich three-layer silicates of the mica group. Because of the firm bonding of the potassium ions to the negatively charged basal planes of the tetrahedral layers, expansion of the crystal lattice with innercrystalline swelling is largely inhibited. In quantitative terms, illite and mica are the dominant phases, followed by low contents of chlorite and disordered kaolinite. In the series of tectosilicates, limited quartz occurs before Na-plagioclase. Goethite, haematite and andalusite are detected as accessory minerals. Accounting for 1 mass%, andalusite has no influence on the ceramics-related properties. Unwanted mineral phases like carbonates, sulphides or sulphates cannot be detected (»Table 1).

In chemical terms, silicon and aluminium dominate clearly ahead of all other elements. The content of aluminium is comparatively high at 22.04 mass%. As fluxes, iron and potassium impact the properties at relatively high temperatures. The high potassium content results mineralogically from the illites and the micas. The total organic carbon is very low and averages around 0.07 mass%. On account of the simultaneous absence of carbonates, only a minimum CO2 emission of 0.26 mass% results during ceramic firing (»Table 2).

3. Ceramics-related characteristics

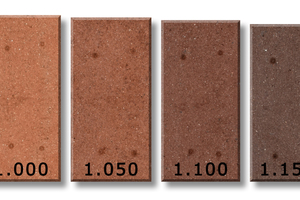

The material exhibits the properties of a finely prepared schist and is free from any unwanted components. The mica schist no longer has to be comminuted energy-intensively, but only homogeneously mixed with other body components. The material does not contain any swelling clay minerals and is therefore unproblematic during drying and preheating. Firing shrinkage is negative to moderate in the lower temperature intervals. Only above 1 050 °C does noticeable firing shrinkage occur, to reach brick properties at 1 150 °C with 4.8 % firing shrinkage. Up to 1 200 °C, the mica schist remains dimensionally stable and does not tend to swell (»Table 3). The fired colours vary as a function of the firing temperature from light red to brown in oxidizing atmosphere (»4).

The material described is suitable for universal use in the heavy clay industry as a low-quartz drying and grogging agent, the predestined application being seen in the facing bricks, bricks and pavers segment. Suitable for the substitution of silica sands and traditional clay schists. It is also predestined to lower the CO2 emissions during firing.

4. Volume availability and final remarks

After separation in the filler removal station, the mica schist can be selectively wetted and stored intermediately until it is collected (»5). Accordingly, a reliable supply is also guaranteed during the winter break. The annual volume available is currently still around 10 000 – 15 000 tonnes. The data specified are guide values and can be subject to the usual natural fluctuation. No liability or guarantee is accepted that the information provided is up to date, correct and complete. All information is non-binding.

![»2 Palaeogeographic map of Central Europe at the time of the metamorphosis in the Carboniferous, from [2].](https://www.zi-online.info/imgs/1/7/4/2/0/8/3/tok_3aab4b624a1f8818c71b4dea3c1ba189/w300_h200_x600_y463_Bild_2-950f8617b2df5095.jpeg)