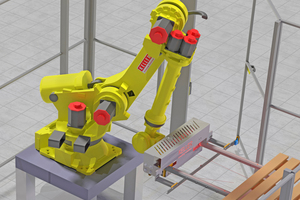

Intelligent robot solution for unlocking of pallet stacks

Pallet logistics is becoming increasingly important in many industrial sectors, especially in the building materials industry. Increasing requirements on building sites, resource efficiency, load securing requirements and internal transport are constantly confronting the companies with new challenges. A flexible system for handling return pallets would increase productivity and provide the necessary process reliability.

Current situation

After their use on the building site, the pallets are returned in locked condition to the brickworks. Before they can be returned to the production process, the stacks must be unlocked manually and put together as sorted stacks. At the same time, they are visually checked for varietal purity. Depending on the production programme, the sorted pallet stacks are delivered to the plant. When the type of product is changed over, the pallet stacks must be removed and exchanged. This results in downtimes in the packaging line.

The Keller HCW solution

So that this task can be performed by industrial robots, a gripper optimized for the specific application was developed. A sensor detects the orientation of the top pallet of the automatically positioned and interlocked pallet stacks. The top pallet is removed and aligned by the gripper and is then delivered to the conveyor of the packaging plant. The innovation of this solution is the integrated measurement of the pallet length. If the dimensions deviate from the nominal pallet, the pallet is automatically removed from the system to avoid any interruption in the production process.

Thanks to the flexibility of the robot and the intelligent control software, the motion sequences can be quickly and easily adapted to the available space. This also allows the later integration of the compact handling solution in many installation situations.

Keller HCW

www.keller.de