Methods of evaluation for raw material suitability and body optimization (Part 1)

A number of veteran methods for evaluating the suitability of raw materials, including the Winkler diagram, the Augustinik diagram and material qualification testing according to Freyburg, are critically examined and accommodated to presently employed product qualities and production technologies. Based on past experience with quantitative mineral analysis, mineral compositions considered optimal for diverse heavy clay product categories are stated. In Part 2, a procedure is described for the pre-optimization of body compositions by means of simple search techniques, linear optimization methods and algorithms.

1 Introduction

For the evaluation of raw material suitability and the optimization of body compositions for heavy clay production, all matters concerning the following two topics must be clarified:

Which properties must the product display?

Which production technology is to be applied to the product?

The properties required of heavy clay products are customarily described in country-specific standards. Beyond such standards, however, additional criteria may also apply to a product’s particular aesthetic appeal in terms of shape, colour or chromatic interplay.

A broad range of production...

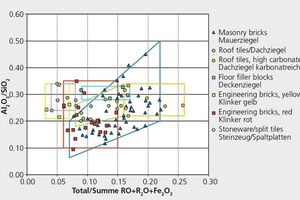

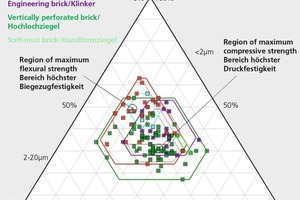

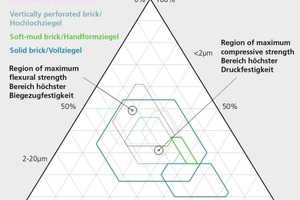

![»1 Ternary diagram showing natural ranges for roof tiles, floor filler blocks, checker bricks and solid bricks acc. to Winkler. 1954 [38] (19 roof tiles,19 floor filler blocks, 6 checker bricks, 3 solid bricks)](https://www.zi-online.info/imgs/tok_28688028fe8a2db42f0c73232bf287ae/w300_h200_x400_y369_101488666_69426d9f86.jpg)

![»2 Ternary diagram with natural ranges for roof tiles, vertically perforated bricks and solid bricks acc. to Schmidt. 1973 [39] (80 roof-tile bodies, 35 vertically perforated brick bodies and 35 solid brick bodies)](https://www.zi-online.info/imgs/tok_4fe1c247dd1760ad12e13ef005ada3b3/w300_h200_x400_y371_101488673_f60e1da14e.jpg)

![»4 Placement of clay and non-clay minerals in the Winkler ternary diagram according to statistical investigation of granulometric expectation values by the author [33, 36]](https://www.zi-online.info/imgs/tok_aa06140d6889e24e80d92905e9afa6bc/w300_h200_x400_y348_101488638_3c8e4f878e.jpg)

![»6 Natural range of especially frostproof roof tiles acc. to Ruppik [70] (various freeze-thaw-cycle /FTC repetition levels) and area of highest packing density with <25% pore volume after tempering of specimens at 600° C (Author’s own research)](https://www.zi-online.info/imgs/tok_a057352ae130d476d4d96ed741a46fba/w300_h200_x400_y346_101488637_95f1d32892.jpg)

![»7 Hypothetical through-fraction curves for the highest flexural/compressive strength after drying, based on data from [81, 82]](https://www.zi-online.info/imgs/tok_5aa3a2ffda24a695712ab47105d19332/w300_h200_x400_y272_101488636_f7d8ccd03b.jpg)

![»8 Augustinik diagram from 1975 [50, 51] for diverse heavy clay products](https://www.zi-online.info/imgs/tok_57bad0c77ed442e8f221aeb8c71d1cf2/w300_h200_x400_y238_101488648_443cde2904.jpg)