Modern engineering in the context of industry 4.0:

How do automation and IT merge together in heavy clay ceramics?

How do automation and IT merge together in heavy clay ceramics?

For many years now, digitalization has been making inroads into more and more areas of life. On the private side, it has become completely normal to use such virtual services as Google Maps, Spotify, LinkedIn, etc. That same trend, however, is also pervading the industry. It is now a matter of course for automation equipment to get its own integrated Web connection, for remote service concepts to be implemented with no substantial loss of time, and for machines to be controlled via apps. This leads to the question of how useful all this can be in and for the industry and which challenges plant operators and mechanical engineers are having to meet.

The entire industry finds itself confronted with new requirements. Product diversity is expanding continuously, even though such individualization must not be allowed to increase the unit cost of products. The only way to bridge that gap is to implement a comprehensive digital value chain along with flexible machine conceptions in which the product design includes digital mapping of the variant diversity from the very start.

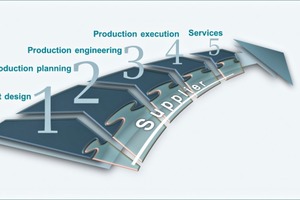

The digital data created at the beginning of the product life cycle are the foundation for all further steps required for producing goods of any kind. Production planning denotes, of course, the planning and design of plant and machinery with the aid of appropriate simulation tools that make it possible to optimize a production facility even before it is built.

In production engineering, the automation technology is sized, selected and configured on the basis of data deriving from the previous phases of processing. Thanks to the availability of appropriate simulation tools, commissioning has now also been partly virtualized, taking place before the real plant is correctly installed and shown to run flawlessly. Finally, actual production is brought to life with the help of manufacturing execution systems (MES) that uninterruptedly monitor, optimize and control the course of production.

At a digital factory, then, virtual elements, i.e., those implemented as software, and real production equipment work together in direct connection. This interconnection between the virtual and real worlds yields new opportunities in the areas of data consistency and continuity.