Modernizing brick plants in India

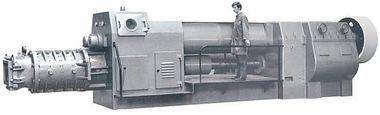

Verdes Clay & Minerals Equipment Pvt. was established in 2011 as a fully owned subsidiary of Talleres Felipe Verdés. Its offices and workshop were built the following year in Hosur, near Bangalore. At the same time a team of executives and key technicians were trained in India and abroad and the local market needs were studied during visits to one hundred local brickmakers and investors. The first wholly India-manufactured extruders were manufactured in the middle of 2013 and the range of machinery was quickly widened. To this day, a dozen different models of machines for feeding, mixing, grinding and shaping have been manufactured and delivered. With these different models and sizes, Verdes can design complete preparation lines for Indian companies. These, of course, can be complemented with bigger or different imported machines from other Verdes manufacturing facilities.

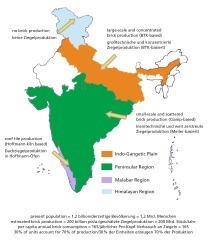

From 2011 to 2014, the first integrated plants were installed and commissioned at the facilities of a dozen customers in five states in North, Central and South India. Some of these customers produce speciality products like floor tiles, ceiling tiles, facing slips, but the majority of them were making standard-sized bricks. However, on the strength of their own prospective market studies and with the full collaboration of Verdes, most of them are moving into the more attractive and higher added value products, mainly thin-walled hollow blocks. They continue to produce standard bricks but with improved quality and performance. The decision of these pioneer-minded industrialists to choose equipment made by Verdes instead of the local manufacturers or the imported Chinese or European alternatives was influenced primarily by two factors:

The innovation and modernity of the European-designed made-in-India machines when compared to competitor products

Excellent service. It has taken a couple of years for the local brickmakers to catch on to the critical importance of this aspect. It involves the project-by-project study of the brickmaker or investor needs, on site, in his own factory or on his plot of land, wherever this may be located in India. Then to propose and supply to him a finely balanced set of preparation and extrusion equipment, fitted to the characteristics of his clay, his present and future products, or to a step-by-step plant modernization if needed. This involves analysis of the physical clay characteristics. For all of this, well-trained engineers are deployed. But equally if not more important is the after-sales service, that is the availability of well-trained local mechanics, of wear parts, the planning and programming with the customer of the availability of parts so that he never has to wait for them, etc. The prospective customers did not value these services initially, as they had never been available from the foreign suppliers nor from the local ones. Brick and tile makers expected to fend for themselves as they had always done. Today they appreciate the importance of this unique Verdes service. The machine supplier provides support during commissioning and provides technical assistance on site

These factors led to follow-on orders from the first customers and are reflected in the marked interest generated by the Verdes customers’ experiences shared by word of mouth to neighbours and colleagues. The Indian heavy clay sector is finally starting to move from cottage-industry levels to more efficient industrial operations, despite the restrictions in clay mining new licenses or approvals to be obtained, etc. The Indian clay brick and tile industry is on its way to provide healthier and safer work conditions, with a lower impact on the environment. The brickmakers also have to drag the construction companies along the path of resource efficiency. These companies do have great interest in building materials with higher quality and resource efficiency, but, at the same time are very cautious when little-known products in a new shape are presented to them. Verdes and its extensive global network of experts and allies will do its utmost to help the clay brick and tile industry in India develop and grow.