Process control for the prevention of lime spalling

1 Context

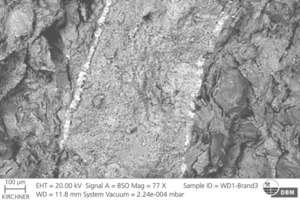

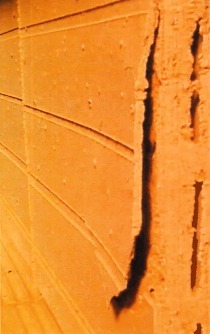

The alkaline-earth carbonates calcite (CaCO3) and dolomite (CaMg(CO3)2) are contained in heavy clay raw materials. Clays intended for use in the production of vertical-core bricks tend to be marly and therefore have as much as 30 mass% carbonate. As long as this lime content is finely distributed, it is unobjectionable, because brick baking deacidifies and bonds it chemically. This reaction makes the brick “microporous” and lowers its thermal conductivity accordingly. If, however, the lime content is lumpy, the familiar damage syndromes can be expected. The reversible endothermic...