Causes and avoidance of firing-related damagePart 1: Diffusion-dependent reactions in the heating-up zone up to 500° C

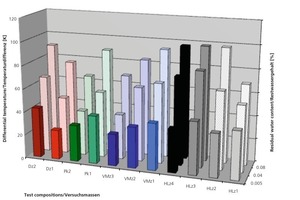

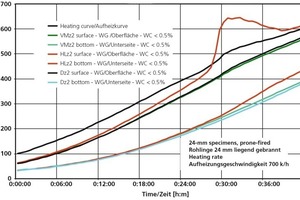

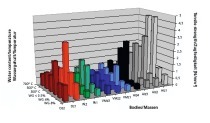

This multi-part contribution summarizes the raw material-dependent reactions that can cause damage to products during the firing process. Thermally induced physical changes in the developing body and the evolution of reaction gases in the course of heating are investigated with regard to their effects on quality impairing processes.

As anticipated, the nature and intensity of such reactions are largely determined by the raw material composition and the targeted type of product. During the heat-up process, a highly porous, energy-rich body for vertically perforated bricks will produce reactions different to those elicited by a dense-firing, highly argillaceous clinker brick body. Due to the diversity of individual reactions, the processes are arranged according to certain temperature ranges to facilitate their detailed description. The technical contributions are therefore subdivided according to temperature, i.e., up to 500° C, 500° C to 800° C and above 800° C. Information on the causes and avoidance of damage is offered to interested readers for case-by-case application to the operational tunnel kiln process.