Renewal of the dryer front increases drying efficiency, saves energy and is corrosion-proof

A team from ROTHO Metall- und Elektrowerke is currently working on the renewal of the dryer front at the brick manufacturer Lücking. A first section at the Warburg/Paderborn plant has already been completed. The ZI editorial team met on site with Lücking authorized signatory Richard Lemke, Claus Lohmann, technical plant manager, and Mario Bäcker, member of the ROTHO management.

Energy losses and temperature instability

Corrosion problems at the front of the chamber dryer, which had been in operation for many years, increasingly led to leaks in the past. The consequences were increasingly greater energy losses as well as temperature fluctuations during the drying process. In addition, the chamber front of the dryer itself became increasingly unstable, exposed to high stresses due to temperatures around 90 degrees Celsius inside the dryer.

To solve these problems, Lücking contacted ROTHO. The company from Neunkirchen in the Siegerland region has been active in the field of brick drying for more than 60 years. ROTHO supplies a complete range of products, from metal dryer supports for all types of bricks to dryer structures and turnkey dryers.

ROTHO developed custom-fit solution

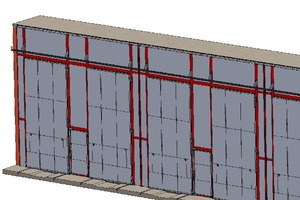

The solution: In several sections, the front with door frame and doors or gates is completely replaced by an aluminum version of the dryer from a conventional metal version that is susceptible to corrosion. For this purpose, the ROTHO team developed a special door frame construction. This consists of extruded tubular frames in a bolted design. The chambers are designed to be separated from each other so that the absorption and dissipation of thermal expansion is guaranteed.

During installation, the most important factors were the appropriate sealing technology and the precise adjustment of the door closure. For this purpose, ROTHO works with a proven system for exact positioning of the gate consoles.

Hardly any interruptions in the production process

Lücking was very satisfied with the solution implemented and the service provided by ROTHO, as well as with the progress of the construction work. As is the case with almost all brick manufacturers, capacity utilization at Lücking is currently very high, which is why lengthy interruptions in the production process would currently be even more unfavorable than they already are. The boom in residential construction, in particular, is creating a great demand for hollow bricks.

The editorial team was able to gain an impression of the manufacturer‘s capabilities during a tour of the plant with authorized signatory Richard Lemke and technical plant manager Claus Lohmann. The company produces around 200,000 m³ of masonry bricks every year, both unfilled and insulation-filled plane bricks. The insulation-filled masonry bricks, which are marketed via the manufacturer association Mein Ziegelhaus, were already certified by the eco-Institut in 2017 as meeting the strictest pollutant and emission requirements in accordance with the latest international research and science.

For some years now, prefabricated brick elements for single-family house construction have been expanding the product range in the factory. They are manufactured from Lücking plane bricks selected by the customer. The floor-to-ceiling, load-bearing wall panels made of plane bricks combine the advantages of high-quality solid brick construction with the efficient element construction method, according to Lücking. They are suitable for load-bearing exterior and interior walls where large wall areas are to be erected quickly and efficiently. Furthermore, the traditional company offers prefabricated brick element and brick ribbed ceilings.

More than 120 years of family tradition

The brickworks, which originated in 1899 from an agricultural operation in Paderborn, now employs 170 people at its production site in Warburg-Bonenburg and has been family-owned for five generations. The company is run by managing partner Joachim Thater, his daughter Theresa Lemke (managing director), Stephan Böddeker (managing director) and Richard Lemke (authorized signatory). Lücking continues to grow and is therefore currently looking for new employees as bricklayers and machine operators for brick production, an employee for the brick assembly plant and a draftsman.

Mit weit mehr als 2.000 Anlagen in über 60 Ländern ist Rotho, laut eigenen Angaben, weltweit führender Hersteller in den Bereichen Ziegeltrocknung und Betonsteinaushärtung. Für die Ziegelindustrie plant, realisiert und wartet Rotho Trocknerbauwerke mit Lüfterwänden oder Drehlüftern, Paletten für Dach- und Mauerziegel sowie Komponenten wie Trocknerwagen oder Belüftungssysteme. Zu den Produkten zählt beispielsweise der neue Niedrigenergietrockner EcoDry, mit dem der Wärmeenergieverbrauch und der Ausstoß von CO2 zu einem hohen Prozentsatz gesenkt werden kann.