Talleres Felipe Verdés opens new laboratory in Vilanova del Camí

The Spanish company Talleres Felipe Verdés is reinforcing its commitment to service and client-optimized solutions with the opening of new laboratory facilities. The event was attended by all the employees from the company´s head office as well as from the subsidiaries in Algeria, Morocco, Portugal and Russia and the local Spanish offices in Málaga and Illescas.

The laboratory ideally complements the extensive range of services such as original spare parts, technical support, training, upgrading of machinery and extended warranties.

Equipment and testing

With its extensive equipment, the new laboratory offers a wide range of tests for analysis of clay and other materials with regard to comminution, shaping, drying and firing. For laboratory testing, the following equipment specially designed by Verdés is available.

Grinding:

Dry: Verdés hammer mill, model 030

Wet: Verdés disintegrator, model 120, and Verdés laminator, model 080

Homogenization: Verdés mixer, model 040

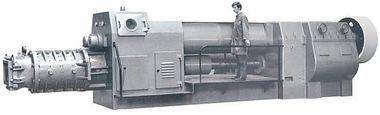

Extrusion: Verdés extruder, model 050-C/O

Clients wishing to conduct tests and measurements in their own facilities can also purchase any of the above-mentioned items of Verdés laboratory equipment.

The laboratory technicians have a range of testing and measuring equipment to assess material behaviour at different stages as well as to determine the characteristics of the raw (wet), dry and fired test pieces. The tests include:

Particle size distribution

Extrusion moisture

Plasticity

Tempering

Shrinkage (dry, fired and total)

Loss on ignition

Bending strength

Water absorption

And for other minerals and biomass, grindability, pelletization, extrudability and other properties can be assessed.

Depending on the product to be analysed and how it is to be used, the Verdés experts choose the most suitable tests and compile an analysis report with the results.

Advantages

A preliminary test allows Verdés to recommend suitable equipment and processes for grinding, homogenizing and/or moulding the product. The client can find out which comminution method is suitable for the clays and the conditions for the extrusion of the raw material. They can also visualize the quality of the final product.

All this helps the client choose the optimal and most efficient solution for the specific application.

Verdés, a leading company in the field of building ceramics, is translating the needs of its clients into high-performance solutions, aimed at improving their products and reducing production costs.

Talleres Felipe Verdés S.A.

www.verdes.com