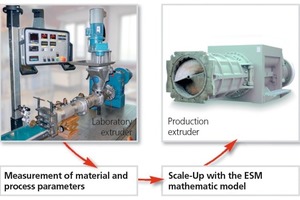

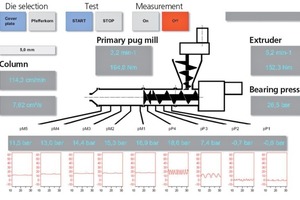

The Händle Extruder Simulation Model (ESM)

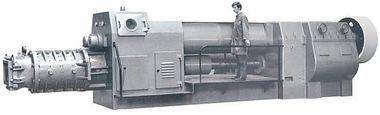

The Extruder Simulation Model developed by Händle in the early 1990s has recently been modernized and optimized. This experiment-based computation model is employed for designing auger extruders. The unique technique puts Händle in a position to provide customers with perfectly engineered auger extruders.

1 Introduction

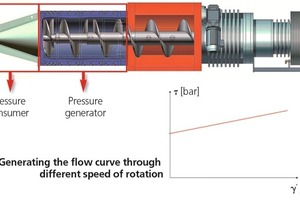

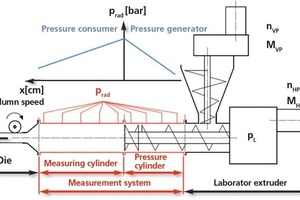

Its main range of application centres on the engineering design of extruders for new ceramic products or raw materials. The Extruder Simulation Model also helps optimize existing auger geometries for achieving crucial improvements in efficiency. As a rule, the object is to minimize friction losses in the extruder‘s barrel in order to reduce energy consumption.

A so-called scale-up enables transition from bench scale to production scale. By way of comparison between theory and practice, Händle has established that the difference between scale-up values and the customer‘s field...