Funding success for two-year hydrogen research project for UK ceramic sector

14.08.2023The British Ceramic Confederation (BCC) has secured around £6million of UK Government funding to support further research into the use of hydrogen as an alternative fuel for the UK ceramics sector, according to a press release from end of June 2023.

The Department for Energy Security & Net Zero has awarded the funding through Phase 2 of the Industrial Fuel Switching Phase 2 Competition, as part of the £1bn Net Zero Innovation Portfolio (NZIP), which supports innovation in the development of pre-commercial fuel switch technologies to help industry switch from high to lower carbon fuels.

The Industrial Fuel Switching funding will allow Phase 2 of the ‘Hydrogen for the Ceramics Sector’ project to be taken forward.

The two-year project will deliver the first-ever demonstrations of 100% hydrogen-firing technologies for the two main types of kilns (batch and continuous) used predominantly across the more than 150 manufacturing sites of the BCC’s 90 member companies; thus providing a key route to help decarbonise the UK ceramic sector (pending availability of sufficient volumes of hydrogen to each site).

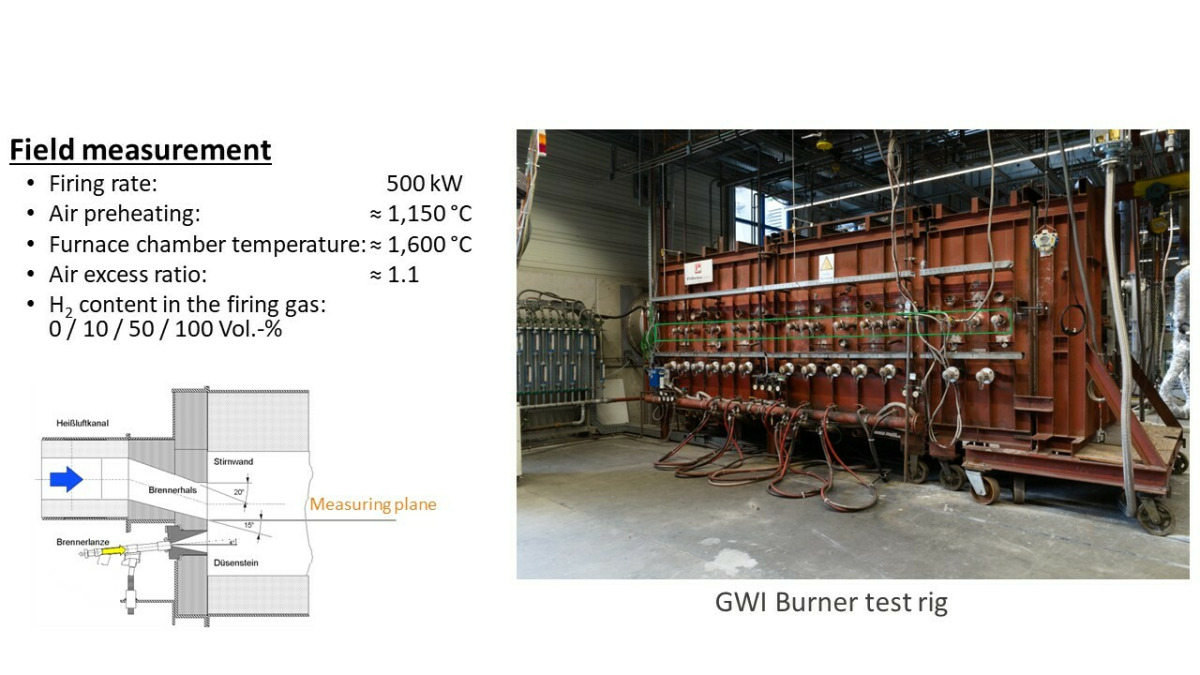

The Phase 2 project follows a successful six-month study, conducted last year, which demonstrated the potential for firing a range of ceramic products using 100% hydrogen, without affecting product performance or properties.

Phase 2 will be supported by 15 ceramic manufacturing companies, spanning all subsectors of the UK ceramics industry (bricks, roof tiles, drainage pipes, floor/wall tiles, sanitaryware, tableware, refractories, and technical ceramics). Following on from the work they carried out for BCC in Phase 1, further support will be provided by the not-for-profit research and technology organisation, Glass Futures.

BCC Deputy Chief Executive Andrew McDermott said: “Phase 1 answered a lot of questions about the feasibility of hydrogen as a fuel for the ceramics sector and the next phase will build upon these outputs. It will evaluate a far greater range of ceramic products, gaseous blends and firing atmospheres in a bespoke pilot kiln, as well as conducting demonstrations on production kilns, to build understanding in using hydrogen within an industrial environment.

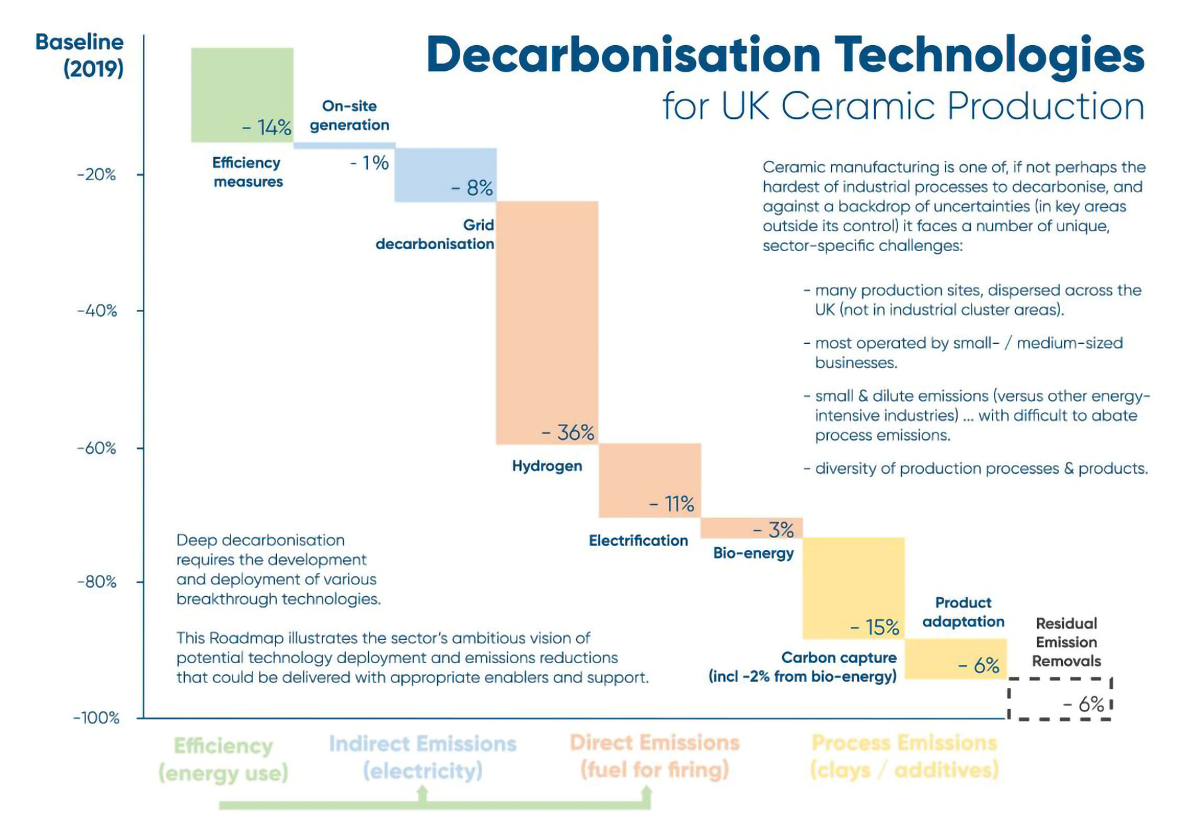

“As for achieving net zero by 2050, the UK ceramic industry’s pathway to meet that target remains uncertain, with many of the technologies that will enable deep decarbonisation, such as hydrogen, electrification, carbon capture and bioenergy, either commercially unviable or simply unavailable.

“Therefore, we expect Phase 2 to demonstrate a key route to help decarbonise the UK ceramic sector.”

BCC Chief Executive Rob Flello said: “UK ceramics play a pivotal role within the net zero journey and are key to decarbonising society.

“Without ceramics, the production of renewable energy is hampered as, without refractories, there is no steel for wind turbines and no glass for photovoltaic panels. Ceramics are needed for electric vehicle batteries. Without high temperature industrial processes, there are no durable homes or commercial properties. There is no heat from waste without advanced ceramics.

“This is a vitally important project, and it is reassuring that the Government is supporting it and believes in the UK ceramic industry’s commitment to decarbonisation.”