Between costs and carbon dioxide - a visit to the purely electrically operated high-efficiency brick plant of Wienerberger Austria

Introduction

The extensive reduction or avoidance of CO2 emissions represents a technical and economic challenge for the brick and tile industry. Wienerberger, founded in 1819 and with more than 200 production sites in 28 countries the world‘s largest brick manufacturer and Europe‘s largest roof tile manufacturer, has made an attempt to address is. At the clay block plant in Helpfau-Uttendorf in Austria, comprehensive measures to improve energy efficiency have been implemented and an all-electric industrial kiln has been installed. Zi editor-in-chief Victor Kapr and editorial advisor Doctor Fritz Mödinger took a tour of the plant and had each step explained to them. In the following report, you can read about everything that has been done to get rid of 90 percent of the CO2 previously emitted, why it is not yet certain that the future of brick production will be electric, and why efficiency is the key.

The Helpfau-Uttendorf plant

Wienerberger acquired the Helpfau-Uttendorf plant near Braunau am Inn in Upper Austria in 1987, where around 50 million non-insulating clay blocks for external and internal walls are produced every year. The site is used for technology demonstrations during operation. For example, an industrial high-temperature heat pump (DryFiciency) for drying processes was used here for the first time in 2019. In addition, a rather low-lime clay is available here, which limits the process-related emissions. For these reasons, the ‘GreenBricks’ project for the decarbonisation of brick production, run jointly by Wienerberger and the AIT Austrian Institute of Technology, was initiated here.

The ‘GreenBricks’ project

The ‘GreenBricks’ project is part of NEFI - New Energy for Industry, an innovation network with 23 projects to develop technological and systemic solutions for the energy transition in industry, funded by the Austrian federal government. Wienerberger, NEFI and AIT had already established a technology partnership and contacts as a result of the previous DryFiciency project. This was built on with ‘GreenBricks’. The aim is to reduce the environmental impact of brick production, the energy and process related CO2 emissions. Compared to the reference period before the conversion, CO2 emissions in the production process are to be reduced by 90 percent and energy efficiency increased by 30 percent. The project began in October 2022 and will be completed in September 2025. The total project volume amounts to around 30 million euros. Five million euros in investment costs and 1.7 million euros in research costs were subsidised by the Austrian government.

Five sub-goals were formulated and achieved as milestones, according to Wienerberger:

Holistic optimisation of the brick manufacturing process’ by means of digital mapping of the brick plant (digital twin) and modelling for techno-economic optimisation at plant level

Development of new, preferably CO2-free clay mixtures with carbon-neutral porosity agents and testing for various production sites and products

Optimisation of the dryer in the system: adaptation of dryer control and commissioning of an extended dryer tunnel with heat pumps

Commissioning and start-up of a highly efficient, electrically powered tunnel kiln

Preparation of technology transfer at plant level within the Wienerberger Group to at least five plants in three countries. Examination of the extent to which electrification of batch and continuous kilns can be transferred to the production of other ceramic products and in other sectors.

Guided tour of the plant

Preliminary remarks

Project manager Rene Pesendorfer leads us through the plant. He explained that production was suspended in summer 2023 as part of the conversion and restarted in autumn 2024. Modification work continued even after that. For example, the heat pumps could only be installed in spring 2025 due to delivery difficulties.

In summary, according to Pesendorfer, the following changes and retrofits were carried out at the plant: A new porosity agent preparation unit because the new mix has a significantly higher proportion of sawdust; adaptation of the clay preparation unit; extension of the dryer while maintaining the same production and retaining internal circulation; installation of three heat pumps; development and installation of an electric pusher plate kiln; adaptation and extension of the setting unit to meet the requirements of the new kiln.

According to Pesendorfer, each unit in itself does not pose a problem. The challenge that the team is currently tackling is to interconnect everything into a system that allows high product quality while complying with the energy limits.

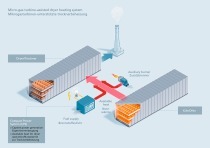

There is no classic combination of oven and dryer. The amount of heat supplied to the dryer from the flash cooling system amounts to around one third of what is required. The remaining heat energy is provided by heat pumps.

As a backup, there is also a gas connection to supply the dryer and steam boiler. According to Pesendorfer, this allows for extended operating options. If the heat pumps fail, there is still enough capacity to generate 100 percent heat. This reserve capacity is important because the plant is primarily used for brick production and only secondarily as a demonstration site. In addition, the existing technical gas infrastructure consisting of pipes and burners is available for any biogas or other CO2-neutral gaseous fuels that may become available at a later date. He does not consider it impossible that the plant could run in hybrid mode.

The goal of reducing CO2 emissions by 90 percent has been achieved, says Pesendorfer. The 30 percent increase in energy efficiency has not quite been reached yet, but he is confident that it will be achieved as well.

Electrical supply

Transformers with a total output of almost 10 MW and a supply voltage of 110 KV are installed in the transformer house. More than 50 percent of the capacity is utilised and there is room for expansion. A new line was drawn from the main transformer station, which is around 5 kilometres away. There is a very well-developed grid infrastructure in the immediate vicinity of the brickworks, as several large consumers were located in the area in the past. The investment in the electrical infrastructure represents a small double-digit percentage of the total cost of the project. A new distribution station completes the supply-side electrical installations.

At 13 MW, the capacity of the line offers potential for retrofitting, while the installed capacity is around 6 MW (3 MW for the kiln, 1 MW for heat pumps and 2 MW for preparing, shaping, transport and others). The photovoltaic system on the roof has an installed peak output of 1 MW. The remaining green electricity is supplied by the local utility Energie AG.

Preparing

The clay preparing system was overhauled and adapted to the new operating conditions.

Dryer

The existing rotary fan dryer was significantly remodelled with a view to low-temperature drying. Some of the air ducts were changed and the volume of the dryer itself was significantly increased.

According to Pesendorfer, the new mixture of clays and porosity agents used in the remodelled plant has different drying properties to the old mixture and is more prone to cracking. For this reason, the dryer guidance had been changed accordingly.

Three heat pumps with an electrical capacity of 330 KW are installed to supply the dryer with heat in addition to the energy from the brick cooling system. These are compression heat pumps with ammonia as a refrigerant. The dryer air is circulated via a condenser. The coefficient of performance, i.e. the ratio of heat output to electrical compressor output, is generally 3.7.

The plant currently produces bricks in two shifts, which are dried and fired in three shifts. Particularly with regard to drying, this leads to relatively higher energy consumption compared to conventional three-shift operation due to irregular loading of the dryer. Empirical consumption analyses of the heat pumps suggest that operation at partial load is disadvantageous compared to operation at full load.

Kiln feeding

The kiln is fed and unloaded using an automated system known as Automatic Guided Vehicles (AGV) instead of a conventional rail system. Alternatives to automatic control are available and can replace the automatic system if required. The system was assembled and supplied by TecnoFerarri. The AGVs allow precise positioning of the setting carriers with the brick packs on the kiln‘s lower conveyor chains with deviations of less than three millimetres.

Kiln setting

Instead of a kiln car, beams made of silicon carbide (SiC) from Saint-Gobain (see ZI 2/25, p. 14) are used as setting carriers on which the brick pack is stacked. Spacers are automatically inserted between the individual layers of the pack during setting. These serve to improve the circulation of hot air in the kiln. The spacers are automatically removed again when the pack is dehacked. Mr Pesendorfer justified the need for partial separation of the bricks in the pack with the risk of melting and black cores forming. The ratio of bricks to air in an electrically operated kiln is far lower than in a classic tunnel kiln, he explains.

Loading and unloading is carried out using SCARA robots (Selective Compliance Assembly Robot Arm). These were chosen because of their small size. They lift the bricks from the AGV onto the SiC beams and vice versa. The alignment of the pack is controlled by a laser. In addition, there are two controls because the gap widths are very small at less than three centimetres.

Kiln

Structure

The kiln is a completely new design by Onejoon GmbH (see ZI 5/2025 for the development of the kiln). The kiln body consists of prefabricated elements with a length of less than 2 metres and is equipped with double entry and exit sluices. Great importance was attached to airtightness. The charge carrier and kiln elements have the same length.

Ceramic firing

The setting is not pushed continuously in the kiln, but is moved at intervals, as in a classic tunnel kiln. The possibility of continuous pushing is being investigated. Technical problems, such as the surface temperature of the heating elements, could prevent such operation.

Firing

The electrically heated tunnel kiln is not a kiln in the traditional sense with an open flame. The kiln is heated with heating rods embedded in the ceiling and side walls, which are clad with SiC. The electrical power of the heating elements used corresponds approximately to the effective firing capacity of a conventional tunnel kiln.

In order to achieve sufficient circulation of the kiln air and thus better convective heat transfer to the product, specific quantities of air are blown into the combustion chamber at relatively high pressure from the sides and from above.

The current cycle times correspond to the usual push times for the type of raw material. Reserves are available to increase the speed.

Hot air is extracted from the kiln. A steam boiler serves as a heat exchanger.

The organic porosification agents lead to the formation of carbonisation gases, which are extracted and discharged into the environment. The use of porosification agents with a less polluting emission spectrum is being researched.

Assessment

After the tour, there was also an opportunity to talk to the Managing Director of Wienerberger Austria, Johann Marchner. He regards the plant conversion in Uttendorf as a technical success. Bricks can be fired purely electrically on an industrial scale, bypassing the majority of emissions and with high efficiency.

The problem of energy and CO2 costs

There is, however, no clear and simple answer to the question of the economic feasibility of the project. At present, fossil fuels are still up to 50 percent cheaper than electricity from renewable sources. This results in significantly higher production costs for the largely decarbonised product. If the entire additional costs were passed on to the market, the cost share of bricks as a building material in the overall trade would increase by a small, single-digit percentage. The extent to which this could be realised still needs to be examined.

Compensating for the higher energy prices by offsetting them against income from the EU Emissions Trading Scheme could reduce the price difference between the energy sources. However, this also requires detailed consideration.

Pesendorfer adds that there are also the not inconsiderable costs of electrifying a plant, irrespective of the electric furnace: in addition to the investment costs for the overland line infrastructure and the technical infrastructure at the supplier, higher costs for grid fees are incurred as electricity consumption increases. Finally, the supply costs of green electricity are still higher than those of conventional electricity. He summarises: ‘You do everything right on the CO2 track, but the businessman turns away in horror’.

Despite the difficult economic realisation, Wienerberger is convinced that the project is on the right track, says Marchner. Firstly, it is a concrete step towards the goal of greenhouse gas neutrality set by the EU. Secondly, it is a way of demonstrating that bricks with high energy efficiency are an ecological building material that is suitable for future construction projects.

Energy efficiency as the key

In view of the still uncertain future of the technical paths to green brick production, both the managing director and the project manager agree that the measures to increase energy efficiency in Uttendorf are currently more important for Wienerberger than demonstrating that electric brick firing is possible on an industrial scale. Pesendorfer explains this from a technical point of view: If 30 - 40 percent of energy were saved in operation and natural gas were used, 60 percent of CO2 emissions could be saved while maintaining competitive product prices. The necessary conversion measures are very efficient in terms of the cost-benefit ratio and could be implemented in all Wienerberger plants in the medium term. That is why part of the ‘GreenBricks’ project is dedicated to the cross-plant transfer of technology and its scaling to larger plants than Uttendorf. This is because the efficiency measures applied in Uttendorf can also help to significantly reduce energy demand, CO2 emissions and therefore costs at sites with different raw material and power supply conditions and larger production volumes.

Due to this uncertainty, the dryer at the Uttendorf plant is still gas compatible, as is the new kiln with modifications. It is conceivable that if a CO2 neutral gas becomes available in the future at an economical price and in sufficient quantities, it will be possible to continue or resume firing with gas.

What will happen next

Wienerberger will continue to pursue both electric firing and efficiency measures. After the brick slip plant in Kortemark, Belgium, and the Uttendorf clay block plant, the other two product groups are to be produced purely electrically, too. A roof tile plant in the UK and a facing brick plant in Kirchkimmen in Germany are to be converted to electric firing.

The knowledge gained in Uttendorf on increasing energy efficiency, setting method, air-brick ratio, interplay between kiln and dryer heat pump, etc. will be tested for transferability to other locations. If these elements are ‘marketable’, they will also be implemented in other plants, regardless of the fuel.

In conclusion, Marchner emphasizes that they are proud to have started the green clay brick project in Austria. He highlights the fact that the success of the project is largely due to the team’s high level of technical competence. The employees accompanied the entire project, acquired the necessary new skills and worked together very well despite many challenges and unknowns.