Brick production – comparison of natural gas and hydrogen

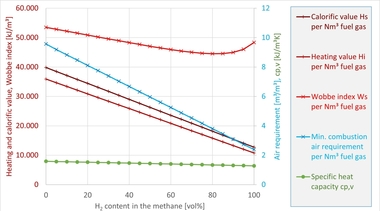

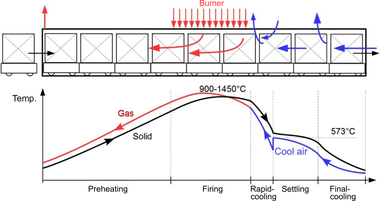

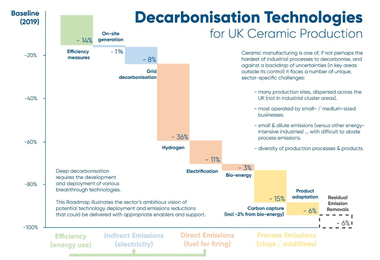

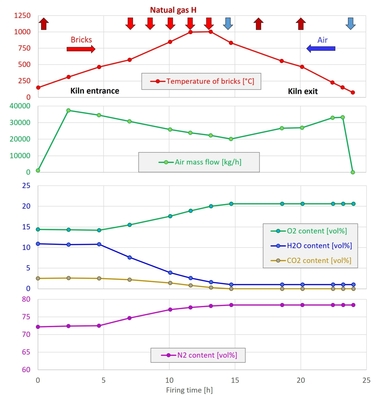

The brick industry needs to reduce energy consumption and CO2 emissions. However, transferring results from laboratory kilns to industrial tunnel kilns on an industrial scale poses a problem. The IAB Weimar uses a chamber kiln as an important bridge for this purpose. It can be flexibly heated with natural gas, hydrogen or freely definable mixtures of both gases. With the help of its precise control system, industrial firing processes can be replicated exactly. Comprehensive data recording enables detailed process analysis. The presentation compares the properties of backing bricks fired in a tunnel kiln with natural gas and in a chamber kiln with natural gas and hydrogen. In the chamber kiln, the main material transformations were reliably documented with the help of continuous exhaust gas analysis and recording of fuel gas consumption. It was found that hydrogen-fired bricks had higher compressive strength. In addition, specific energy consumption was reduced. This shows that natural gas can in principle be replaced by hydrogen – provided that sufficient green hydrogen is available at reasonable cost.