Energy efficiency – the order of the day (part 1 of 3)

Reducing energy consumption is a key problem for the brick and tile industry in Europe and, in the long term, worldwide. The significant rise in energy prices over the past few years directly suggests a more economical utilisation. In the future, rising CO2 prices will increase energy prices. In his new book “Optimum drying and firing of bricks”, Dr Stefan Vogt discusses in detail the ways in which energy can currently be saved. This article, which is published in three parts, presents an extract from this.

Overview

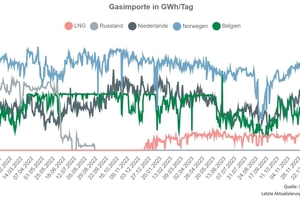

A spectre is haunting Europe – no, not the spectre of communism, but that of high energy prices. After the politically motivated gradual throttling of the natural gas supply rates to Germany by Russia in June 2022 (»Fig. 1), the spot market reached a peak value in early September 2022 with a gas price of over 300 euros/MWh, that is ten to 15 times the price of previous years. On 26 September 2022, the North Stream Pipelines 1 and 2 suffered an act of sabotage, as a result of which one of the main routes for gas supply to Europe was destroyed.

In the meantime, gas prices on the spot market have fallen back to a lower level, but are currently still around twice as high than four years ago. As the price of electricity is aligned to the most expensive price of electricity generated by gas-powered power plants, the electricity prices on the spot market have risen to the same extent as the gas prices. It is almost impossible to forecast future energy prices because the roadmap to climate-neutral energy production is interpreted differently in the various regions of the earth, and in addition because the current players on the energy market are pursuing different interests.

Energy will probably never again be as cheap as it was four years ago. That this is to do with the switchover to renewable energy sources, especially when it comes to electricity prices, is explained based on the example on the planned transition from fossil to renewable fuels in Germany.

Because of the persistently high energy prices, thought must be given about how brick plants can survive in future in competition with other less energy-intensive construction materials. In spring 2021, the Federal Association of the German Brick and Tile Industry presented its Roadmap 2050 for the transformation of the clay brick and tile industry for the switch to renewable fuels [1]. This article underpins the technological routes mapped out in this roadmap and shows that the systematic deployment of new drying and firing technologies can enable 60- to 70-% reductions in energy consumption compared to average consumption rates today. With such savings, it will be possible to cushion the impact of high energy prices. With new technologies, the clay brick and tile industry would therefore be equipped to face the competition ahead. That does not, however, make any difference to the currently drastic slump in building activity, which can be attributed to the monetary policy decisions by the European Central Bank as well as other general political and economic factors.

Establishing energy supply on the basis of renewable energies

The development of energy supply on the basis of renewable energies is a massive undertaking. In 2022, a total energy consumption of around 2400 TWh was registered in Germany according to information released by the country’s Federal Environment Agency. Of this, industry and business together consumed around 1000 TWh, transport 700 TWh, while households also accounted for around 700TWh (»Fig. 2). Two thirds of the 2400 TWh in total, that is around 1500 TWh, were covered direct with fossil fuels like lignite and coal, mineral oils as well as natural gas, while only 226 Wh (9.4 %) came from renewable resources.

However, electricity consumption is at the focus of public debate on the transition to renewable energies. Here, according to information from Germany’s Federal Network Agency, the share for electricity generation only amounted to around 500 TWh in 2022, that is only around 20 % of the total energy consumption. If, in a first step, the currently communicated ideal case of a complete switch to electric vehicles and heating of all households with heat pumps to replace the use of natural gas and mineral oils is assumed, then an additional electricity requirement for transport and households of around 240 TWh could be derived based on »Fig. 2 (assumptions: heat pump COP= 3.5; consumption of car with combustion engine= 100 kWh/100km; electric car= 20 kWh/100km). The total electricity consumption in Germany necessary then would therefore increase by around 50 % compared to the 2022 level, that is providing energy-saving measures are initially neglected.

In the second step, if, for the purpose of simplification, it is assumed that the fossil fuels currently used in industry and business (coal and lignite, natural gas, mineral oils) are substituted with green hydrogen, a demand for hydrogen totalling 515 TWh results. That corresponds to an annual requirement of around 15.5 mill. t hydrogen. As green hydrogen is produced by means of electrolysis from water in a process powered by electricity, the total electricity requirement further increases as a result of the production of green hydrogen. For the production of one tonne of hydrogen, around 50 MWh electricity is needed. If a quantity of 515 TWh were produced in Germany with green electricity, then, based on the state of the art, an additional 775 TWh would be consumed. The imbalance between consumed and generated energy shows that the production of green hydrogen is currently not economical and only expedient in the case of an electricity oversupply. But more significant is the conclusion that the electricity requirement in Germany will increase sharply in future. According to the much simplified analysis derived from »Fig. 2 and the current goals for energy transition, the consumption of electricity in Germany may triple compared to the current situation unless there is further technological progress is made.

So, what direction will the future electricity prices take? For Germany, there is a pretty clear answer to this. Because of the coal phase-out planned for 2030, a large number of new gas-fired power plants must be built to replace the coal-fired power plants. In addition, the expansion of wind and solar energy is being expedited, as a result of which further costs are incurred. Since, despite an oversupply of wind and solar energy at times, dark doldrums can occur for several days all over Europe, to cover the total demand for energy, a full number of conventional power plants must be kept in reserve. To cover the additional energy requirement during the dark doldrums, storage solutions should be created. It is not yet completely clear what technologies will become established for this storage (battery or hydrogen storage, pump storage plants). Ultimately, the future electricity supply will stand on three pillars, the power plant park with natural gas or hydrogen, the wind and solar parks and energy storage facilities. Not to be forgotten in this context is the necessary development of the distribution networks for transport of the electricity. All these new installations will incur enormous investment in the coming decades, which ultimately must be paid for by the electricity customers. Because of the provision of three instead of just one energy generation system, and consequently the fixed costs for these systems, electricity prices will automatically persist at an extremely high level.

What renewable energy sources are expedient in clay brick and tile plants

How will clay brick and tile plants be heated cost-efficiently with renewable energy sources in future? Brickmakers have always been variable in their use of fuels, whether these be solid, liquid or gaseous. For instance, renewable energies with regionally limited availability from wood gasification as well as bio- or landfill gas can also be used. Given a low-cost availability of hydrogen, this will also be usable in the brick plants, after the usual initial teething problems have been overcome [2, 3]. The preconditions for the use of hydrogen are, however, not given in the immediate future because:

hydrogen will not be available in sufficient quantities in the next few years

the energy balance for the production of green hydrogen from water with the currently available technology is negative

on account of the electrolysis, the price for green hydrogen in Germany is automatically higher than that of electricity

In 2021, around 3130 TWh hydrogen (green, grey and blue hydrogen) was produced worldwide. To substitute fossil fuels, Germany alone needs the above-mentioned annual total of 515 TWh energy. Germany’s share in global energy consumption in 2016, however, was only 2.4 %.

If green hydrogen in Germany is to be produced from an intermittent or continuous electricity surplus, 775 TWh would have to be expended. In 2023, 123 TWh were generated in Germany with wind energy and 62 TWh with solar energy. To generate the electricity necessary to produce the hydrogen needed, the current capacity of the solar and wind parks would therefore have to be more than quadrupled just for hydrogen electrolysis. In this context, it should also be noted that the solar and wind parks require much larger land usage than conventional power plants operated with high-calorific fuels. This circumstance leads to problems with acceptance by the public. In the last ten years, only between 1.5 and 6.5 TWh of new wind power capacity has been put into operation each year. The addition of new solar power plants has been on a similar level.

On sober consideration of the facts, we can surmise that the transformation of the energy supply, especially with regard to green hydrogen, will take longer than so far propagated by policy makers. For this reason, we may presume that natural gas will be used in clay brick plants for many more years if heating of the dryers and kilns with electricity does not become established. The initially absurd idea of using expensive electricity to heat dryers and kilns is turned on its head if we look at the current electricity and hydrogen prices. At present green hydrogen costs around 180 euro/MWh and is therefore almost twice as expensive as electricity and three times more expensive than natural gas. However, the price of natural gas price will increase significantly in future owing to the rising costs for CO2 certificates. At a gas price of 60 euros/MWh and a certificate price of 80 euros/t carbon dioxide, the CO2 price already accounts for 16 euros/MWh. Green hydrogen produced in Germany, however, will in future, on account of the negative energy balance, always be around twice as expensive as industrial electricity. Accordingly, the use of electricity for heating dryers and kilns seems less horrifying, especially as green electricity is more easily available and cheaper than green hydrogen.

Potential of various energy-saving measures

Energy-saving measures are being systematized in most clay brick and tile plants with the introduction of energy management systems in compliance with ISO50001, leading to ongoing improvements. The modifications made for energy saving are wide-ranging. Most measures generally lead to maximum energy savings of around 10 %. Some of the changes achieve energy consumption reductions of less than around 3 to 4 % and can therefore not be significantly confirmed against the usual fluctuations in fuel consumption. Relatively large potential energy-saving measures between 10 and 20 %, as feasible with the introduction of exhaust gas heat exchangers or heat pumps as well as rapid drying and gas-tighter tunnel kilns, have hardly been implemented in recent decades because they require long refinancing periods. Energy was always still so cheap that technological change was not absolutely necessary. This situation has changed with the general growing awareness and recognition of climate change in society. Topics like dematerialization, CO2-neutral raw materials and fuels along with new drying and firing technologies are the subject of increasing discussion. The CO2 footprint of a process is a key criterion and is taxed on the basis of CO2 certificates. At the same time, energy prices are getting more expensive, additionally so because of the loss of the formerly low-price natural gas supplies from Russia.

For this reason, technologies with maximized energy saving to mitigate the increase in the fuel costs are of huge importance (»Table 1). Energy-saving measures with a potential of 10 % maximum tend to be of minor interest. Energy-saving measures with a potential between 10 and 20 %, which are described as bridging solutions for existing dryers and kilns, tie up a relatively large amount of capital, without enabling any stronger impact for the future. Ideal are technologies that can largely offset the increased price of new heating energies (bio, landfill and wood gas, green hydrogen, green electrical energy). These technologies include high-efficiency kilns for clay blocks with a saving potential of around 60 to 70 % [86]. For reasons of efficiency, these carless and gas-tight fast-firing kilns only give off heat to the dryer in the magnitude of the input heat-releasing raw material enthalpy. As a result, there is then greater focus on the energy required for drying on account of the lower quantities of heat in the combined heat supply system.

For clay blocks, the heat required by the dryer can be roughly three times higher than the consumption of the kiln (»Fig. 3) [4]. Reflected in this assessment is the ratio of the enthalpies of the drying and firing processes needed for material transformation. While kilns with raw materials with low organic content consume a raw materials enthalpy of around 250 kJ/kg fired ware for formation of the solid brick body, the necessary evaporation enthalpy of the dryer ranges – depending on the moisture content of the extruded bricks – between 500 and 1000 kJ/kg fired ware. The extensive supply of the dryer from the combined heat supply system so far has obscured this situation [4]. One potential solution for substituting the heating energy missing from the combined heat supply system in future is the systematic implementation of rapid drying technology [39– 50] in combination with the use of heat pumps. In addition, in the summer months, drying can be complemented by the use of ambient air drying [10– 13].

Modification of existing plants

The energy-saving measures listed in »Table 1 represent only a small selection of the possible energy-saving measures. In the following, several measures for existing plants that could play a part in the future or that have received too little or too much attention in respect of their effectiveness are considered in more detail.

The temperature of the hot air at the dryer is a seldomly considered factor influencing energy consumption. For a minimized drying time and a low energy consumption of the dryer, the temperature of the hot air supplied to the dryer must be as high as possible [4– 9] (»Table 2).

The maximum permissible hot air temperature has to be determined in drying tests. Depending on the temperature of the supplied hot air, different brick temperatures result. In the first drying section, the brick and exhaust air temperatures roughly correspond to the cooling limit temperatures. If, for example, the hot air temperature is increased from 120 to 180 °C, the brick and exhaust air temperature (cooling limit temperature) rises from around 37 °C to around 45 °C. The low temperature increase of the bricks of 8 °C contrasts with a considerable increase in the water absorption capacity of the exhaust air of 23 g/kgdryerair (+66 %). To the same extent, the amount of exhaust air necessary for transport of the water vapour expelled in the dryer can be reduced. As the exhaust air loss of the dryer including the evaporation heat contained in this represents the largest loss in the thermal energy balance of a brick plant, in the selected example, the specific thermal energy consumption of the dryer falls by more than 27 %.

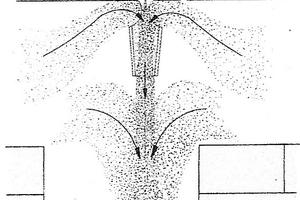

Circulation systems are relatively expensive, and in some cases they can lead to undesirable side effects [15]. High-pressure air injection systems have been developed as an alternative to circulation systems and can achieve similarly effective circulation. Air jets with a nozzle diameter smaller than 10 mm are operated with a pressure of 20000 to 30000 Pa. Even with more than 30 air jets, the air/brick ratio of cold air introduced by the air jets does not exceed the value of 0.15. With such a large number of air jets, a good circulation effect can be achieved at low cost over a large kiln section (»Fig. 4).

In practice, preheating of the combustion air mostly leads to lesser effects than desired and disrupts proper kiln operation. It should only be implemented if too much heat is available in the combined heat supply system for the dryer. However, this circumstance has deeper-reaching causes, which generally– apart from very high combustible content in the raw material– can be eliminated with the reduction of cooling heat extraction at the top of the kiln [4]. Lesser effects than intended are obtained because the combustion air temperatures applied are often only between 80 and 150 °C. This is to do with the fact that the air supply cross-sections of the existing burners have not been adapted to conditions for even hotter burner air or the replacement of the burners would be too expensive. Moreover, the necessary insulation around the air supply pipes to the burners hinder the access needed to adjust the burners, and working with the burners can, as experience shows, lead to burns. For energy saving, it is easier to let the hot air flow out of the cooling zone and direct into the firing zone, without this being first extracted and then re-introduced indirectly into the firing process.

A good alternative to combustion air preheating in this case is the use of pure gas burners without or with only low addition of burner air (»Fig. 5). For intensive premixing of the jet of natural gas with the combustion air in the firing slot, a Venturi nozzle can be installed upstream of the burner lance outlet. As a result, the flame is shorter than without Venturi nozzle. The big advantage of the pure gas burners is that these do not need any or hardly any additional burner air that must then be heated to the necessary gas temperatures in the firing slot. If, however, better temperature balancing or a relatively high oxygen availability is necessary in the firing zone, the absent influence of the burner air cannot be neglected. For this reason, pure gas burners are usually only used in partial sections of the firing zone.

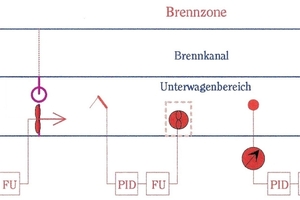

One effective method for retro-sealing kilns, especially tunnel kilns with an inspection channel, is undercar pressure regulation. The objective here is to reduce the gas flow (blowby) from the firing channel to the undercar area and vice versa by realizing a similar pressure profile in the undercar area as in the firing channel. In addition, the undercar area is typically cooled by means of fans. To fulfil both purposes, in the undercar area, pendulum flaps, bulkheads and shoulders are installed at the kiln entrance and exit to maximize sealing of the undercar area (»Fig. 6). In addition, all doors to inspect the undercar area must be kept constantly closed. The undercar area is then, for example, divided into three zones that roughly correspond to the preheating, firing and cooling zone. In the area of the preheating zone, normally negative pressure prevails in the firing channel. For this reason, in the undercar area, to generate negative pressure, a fan is used to extract air and transport it in the direction of the firing zone. The differential pressure between the firing channel and the undercar area is measured at one point with a ring manometer and automatically regulated to around 0Pa. In the adjacent downstream firing zone, a slight overpressure can already prevail. In addition, this area heats up increasingly as a result of the heat given off from the heated-up tunnel kiln car structures. For this reason, fresh air from the kiln room is blown into this area by means of a temperature-controlled fan. The pressure in the firing zone is then regulated by means of a third fan. This regulates only the pressure in the undercar area and not the difference in pressure to the firing channel, so that the pressure fluctuations prevailing there caused by the constant switch-on and -off of the burners do not cause regulation oscillation. In the cooling zone, which is mostly pressurized, a fourth fan is used to blow air into the undercar area, which is regulated based on temperature. As a result, the maximum necessary pressure is achieved with the lowest cooling air supply.

The measures in existing plants with a saving potential of more than 10 % energy include the use of heat pumps on dryers, the use of exhaust gas heat exchangers on kilns, and the switch to significantly lighter weight tunnel kiln cars than those common today. In future, heat pumps can make a contribution to energy saving in dryers (»Fig. 7). Corresponding heat pumps with the necessary output range for brick plants have been available for several years. Heat pumps consist of the following main components:

Heat exchangers or cooling towers for heat recovery of the perceptible and latent heat from the exhaust air

A system of water pipes with pumps and fittings as well as storage tanks for transport and storage of the warm and hot water flows

One or more heat pumps to generate hot water temperatures between 80 and 90 °C

Internal or external heat exchangers on the dryer to reintegrate the recovered heat

A first key aspect crucial for the efficiency of the use of heat pumps is the theoretical recovery rate of the perceptible and latent heat from the exhaust air of the dryer. The recovery rates of the various dryer types differ on account of their typical exhaust air conditions (»Table 3). The heat recovery rate is essentially determined by the water content of the exhaust air, because the latent heat in the exhaust air is greater than the perceptible heat. As the typical water content of conventional continuous and chamber dryers with 44.2 and 45.9 g water per kg dry air is relatively equal, the theoretical heat recovery rates are similar at around 64 to 68 %. A much higher potential heat recovery rate is exhibited by rapid dryers because these offer a high mean water content of 124.7 g water per kg dry air. As a result, the heat recovery rate increases to 85.6 %. With consideration of the fact that a rapid dryer only needs around a third of the exhaust air compared to conventional dryers, the heat recovery rate increases arithmetically even to 90.8 % because of the falling percentage of ballast air.

In the second step, the heat gained in the exhaust air must be raised to a higher temperature level by means of a heat pump and then reintroduced into the dryer via dryer-internal and -external heat exchangers. The efficiency of the process is limited by the low water temperatures of 80 to 90 °C produced by the heat pumps. In addition, in the dryer curves, end-drying temperatures in excess of 80 °C are often used for relatively long periods of time in the drying curves. Accordingly, the real realizable thermal energy savings with heat pumps fall in conventional dryers to around 60 % and in rapid dryers to around 65 %.

Up to now, in conventional dryers, only a maximum of 15 to 20 % thermal energy is saved with the use of heat pumps. This circumstance is explained by the fact that the combined heat supply system of the kiln generally gives off so much energy for drying that no greater saving potential is available. There are plants in which at least at times too much energy is given off from the kiln to the dryer, so that in the combined heat supply system, hot air must be blown off via the roof. For the use of heat pumps, therefore, plants are selected in which the additional heating at the dryer makes a big contribution. In future, to supply conventional dryers and kilns in a combined heat supply system with a maximized percentage of heat with a heat pump, it is necessary to limit the cooling heat given off by the kiln to a large extent based on reduction of the raw material enthalpies and resetting of the cooling zone [4]. An efficient use of heat pumps is opening up, however, especially with the application of high-efficiency kilns or in the isolated kilns installed without a combined heat supply between kiln and dryer.

The use of exhaust gas heat exchangers in tunnel kilns (»Fig. 8) becomes financially interesting for exhaust gas temperatures above 200 °C. Such high exhaust gas temperatures occur primarily in kilns firing clay blocks with external thermal post-combustion or kilns for roofing tiles with preheaters. Air-air, air-water and air-thermal oil heat exchangers can be used. For repair work on heat exchangers, a bypass is implemented. The saving effect of the exhaust gas heat exchanger is aligned to the prevailing exhaust gas temperature, the possible minimum gas temperature based on the pollutants contained after the heat exchanger and the air/brick ratio of the exhaust gas.

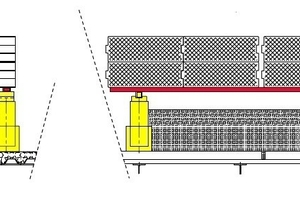

Even in modern tunnel kilns, the ratio of the cars to the setting mass ranges in the region of 0.4 to 0.8. Moreover, draught blocks or kiln furniture with a relative weight of 0.05 to 0.25 relative to the brick mass are often still used. So in the firing process, almost the same weight as the setting is heated again in the form of car structures and kiln furniture. It can be assumed that, towards the end of the firing zone, the different decks of the kiln cars reach on average around half the firing temperature of the bricks. The kiln furniture (hollow platforms, setters, draught blocks) even near the firing temperatures. To heat up and cool down the cars and kiln furniture, additional quantities of air are needed in the preheating and cooling zone. As a result, the quantities of exhaust gas and cooling air at the kiln increase. From information on the relative car and kiln furniture weights (0.4 to 1.0) and the temperatures reached (half of the firing temperature), it can be derived that the kiln cars increase the specific thermal energy consumption by 20 to 50 % in conventional kilns. For existing tunnel kiln cars in conventional tunnel kilns, a high saving potential results when the weights of the car superstructures are radically reduced. The car superstructures used up to now must be replaced by much lighter structures. The possible target range lies at a car to setting mass ratio of 0.25 to 0.3. For this, the heavy setting decks used up to now are replaced by individual supports on which SiC beams are arranged for supporting the clay blocks (»Fig. 9). Between the supports, very lightweight insulation materials can be used as these do not perform any structural functions. Depending on the situation for the old car superstructures, energy savings up to 35% are possible in conventional kilns.

![»Fig. 3: Main heat flows at the dryer and kiln in a clay block plant [4]Wärmefreisetzung Ofen = Heat release in the kilnZusatzheizung Trockner = Additional heating for the dryerWärmeverbund Ofen-Trockner = Combined heat supply system for the kiln and dryerWärmeverbrauch Ofen = Heat consumption of the kilnWärmeverbrauch Trockner = Heat consumption of the dryer](https://www.zi-online.info/imgs/2/1/4/8/3/1/0/tok_5fcca098744561fafb8a8b1620fa94ef/w300_h200_x600_y539_Bild_3-73860873d6bd6e6b.jpeg)