Fully automatic AI-based dry brick inspection

Ibea GmbH Hamburg has been building testing and sorting systems for 35 years.

Since 1991, ibea has installed approximately 6,500 such systems worldwide, particularly in the packaging and construction industries.

Now, ibea has developed a new dry (roof) brick inspection system that automatically inspects dry bricks, with or without engobe coating, or non-glossy fired clay roof tiles. Inspection directly after the brick press or after engobe coating (or after firing) offers the following advantages:

Pressing errors are detected immediately (incorrect pressing, adhesion, edge or shape errors)

Warping is measured and evaluated

Errors such as cracks or breakages in the area of the batten lugs or round fold are inspected

Engobe errors such as missing application or incorrect colour are inspected

Any faults found are sorted out before the kiln (or after firing). The material can possibly be returned to the cycle.

Inspection before the bricks are fired prevents series faults and thus stops unnecessary further processing. Firing energy and material are saved. In addition, kiln capacity is only used for bricks without faults.

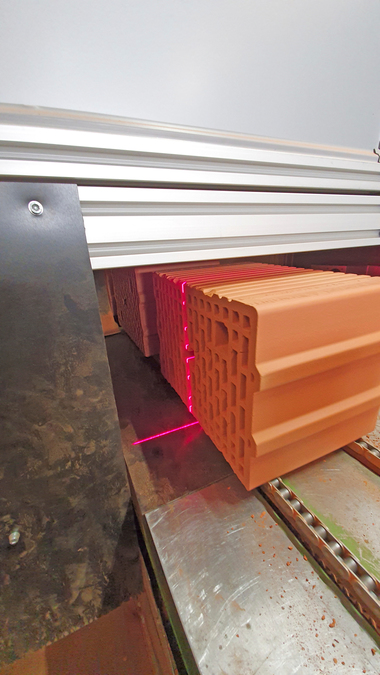

The system has very small dimensions (1 * 1 metre, 2.3 metres high), as existing production facilities are usually very cramped.

The system has 4 cameras. 2 cameras monitor the top view, one 2D for the engobe colour and one 3D for all pressing defects, cracks and deformations. The front sides are recorded in colour via 2 opposite mirrors to inspect the top side and the nose side.

In addition, the system is completely AI-based and can be fully configured and isready to start with a single teach-in button press. It can process 600 bricks per minute. All cameras provide a high-resolution colour image.

Of course, comprehensive statistics and all status signal connections are available. The system can be monitored and operated remotely. This also allows service work to be carried out if necessary.

The compact design and use of state-of-the-art components result in a very low price that can be amortised within a year.

The system can be used for all brick formats in the dry area or, after firing, for all bricks without a glossy engobe. In the latter case, the system can also be supplemented by a sound inspection.