„Intermittent Microwave Drying for the Brick Industry“ Workshop

On 18 October 2022, the workshop „Intermittent microwave drying for the brick industry“ took place at the Materials Research and Testing Institute at the Bauhaus University in Weimar (MFPA) in Germany. The aim of the organisers was to inform about the research project of the same name with a duration from 01.01.2020 to 31.12.2022, the results and next steps. Partners were the Institute of Process Engineering at Otto von Guericke University Magdeburg (IVOvG) and the Institute of Brick Research Essen e. V. (IZF). Around 30 participants, scientists, experts from brick companies and suppliers, gathered on site or were connected online.

Why intermittent microwave drying?

Dr Anne Tretau (MFPA) introduced the AiF project funded by the Federal Ministry for Economic Affairs and Energy. The starting point was that the brick industry must find ways to generate the process heat needed for drying and firing independently of fossil fuels by 2045.

The project addresses this problem with two prerequisites: Electrification using renewable energies is an efficient or the most efficient option for CO2-neutral process heat. Dryer and kiln should be optimised separately.

The aim of the project was to explore and understand microwave dielectric heating for brick drying. A key challenge was that clay bricks have comparatively small pores and large material thicknesses compared to other microwave drying products.

The intermittent approach arose from previous experiments at IZF. Moist clay bodies tend to crack and fracture due to poor mass transfer kinetics at high evaporation rates. Intermittent microwave drying, i. e. a combination of microwave and convection, was proposed as a solution.

Relevant material properties

Dr. Tretau gave an overview of the material properties relevant for the investigation of intermittent microwave drying in the subsequent lecture. Corresponding data, experimentally determined on four test masses (vertically perforated bricks, facing bricks, paving bricks, roof tiles) with different initial water content and dry bulk density, were presented and compared.

Permittivity and wave propagation

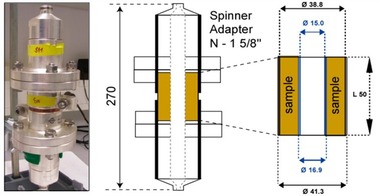

In the third lecture, Frank Bonitz (MFPA) explained which variables influence the determination of permittivity. These are, as he explained on the basis of experimental results and modelling, material composition, moisture, density or porosity, temperature and working frequencies. Knowledge of permittivity is essential to determine the propagation of electromagnetic waves in the material, the field distribution and the absorbed energy. This forms the scientific basis for the development or optimisation of microwave-based drying and firing processes.

Experimental microwave drying of blanks

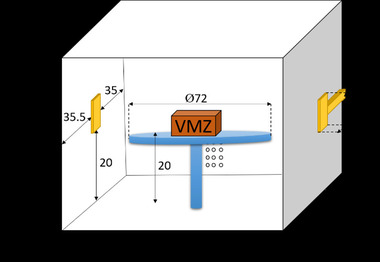

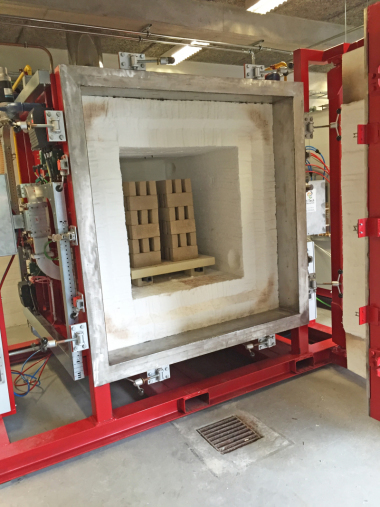

In the fourth lecture Ralf Wagner (MFPA) presented experiments on experimental microwave drying of blanks of different product groups as well as the results. The tests were carried out in a microwave tunnel, in the laboratory and in the Magdeburg test facility. The results of these test series showed, among other things, that the microwave power input can be adapted to the material and that samples with a higher strength (drier samples) tolerate a higher power input.

Technical feasibility and energy efficiency

Dr.-Ing. Nicole Vorhauer-Huget (IVOvG) gave a presentation on the technical feasibility and energy efficiency of intermittent microwave drying, reporting on the tests in the test facility in Magdeburg and the results. Among other things, it was shown that an intermittent energy input produces uniform temperature profiles and reduces the total energy consumption. The energy efficiency of microwave heating was between 62 and 80 percent. Further increases in efficiency depend on material properties, water loading, temperature and geometry.

Experiments on vertically perforated bricks and brick slips

In the last lecture of the workshop, Lucas Briest, from the Institute of Process Engineering at Otto von Guericke University Magdeburg, reported on experimental investigations on vertically perforated bricks and facing bricks with different process modifications. It was shown that fast microwave drying depends on multiple parameters and that vertically perforated bricks can be dried in four hours by experimental optimisation.

Interest in microwave drying exists

A lively, open discussion ensued at the end, in the course of which it became clear that there is interest on the part of brick manufacturers in further research into both brick drying and firing with microwaves. Open questions and problems were also identified that need to be addressed in the following projects. The organisers rated the workshop and especially the subsequent discussion as very positive.