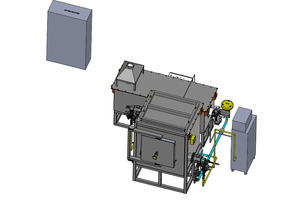

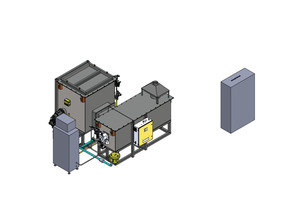

Laboratory furnace with mixed hydrogen-natural gas firing by Industrieofenbau Bader & Scheffer for the investigation of the effect of hydrogen as a fuel gas on various product families (mainly ceramics)

The company Industrieofenbau Bader & Scheffer GmbH was commissioned to supply a laboratory furnace. The plant has a square useful chamber with a side length of 500 millimetres. A special feature is the automatic hydrogen-natural gas mixture firing. The proportion of hydrogen in the natural gas mixture can be variably adjusted.

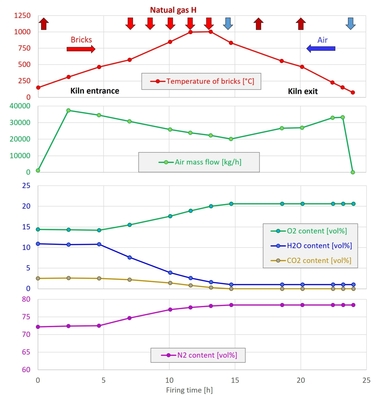

The laboratory furnace is used to determine and research the interactions between the product and different fuel gas atmospheres and the effects on the water and carbon dioxide contents.

The fuel gas composition, the desired calorific value per burner and the desired lambda can be preset by the central control system.

Very precise MFCs (mass flow controllers) are installed on the gas supply side for this purpose. Special attention was paid to the repeat accuracy of the mixed gas generation.

To check the hydrogen content in the mixed gas, a hydrogen analyser is installed downstream of the mixing unit. Fluctuations in the hydrogen content in the natural gas supply, which are likely to become much greater in the future as a result of the German government‘s hydrogen strategy, are compensated for by this measure. The analyser‘s feedback automatically adjusts the mixing ratio of hydrogen and natural gas to the specified ratio. This also ensures that the analysis results remain comparable in the future.

Burners from WS Wärmeprozesstechnik GmbH are provided as firing equipment. With this special series of burners, between 0 and 100 percent hydrogen can be burnt directly without any structural modifications.

The variable combustion air quantity (specified by lambda, gas composition and heat output) is calculated by the PLC (programmable logic controller) and set on the system without further intervention. In order to achieve a high degree of safety, all measuring devices for setting the volume flows are designed redundantly.

Under oxidising conditions, firing temperatures of up to 1300 degrees Celsius are possible with this system.

A thermal oxidiser directly connected to the kiln cleans the exhaust gases from escaping organic matter. The cleaned waste gas is led over the roof with an exhaust air system.

This system is supplemented by a stationary exhaust gas analysis system from MRU. All measured values for nitrogen oxides, sulphur dioxide, carbon monoxide, carbon dioxide and oxygen are continuously recorded.

An interface to the database makes it possible to store all measurement data relevant to burner technology, such as gas flow rates, air flow rates, flue gas values, etc.

The commissioning of the kiln is planned for the end of 2023. Initial experiences are expected in the first and second quarters of 2024. These are going to be published as well.