Matching market trends

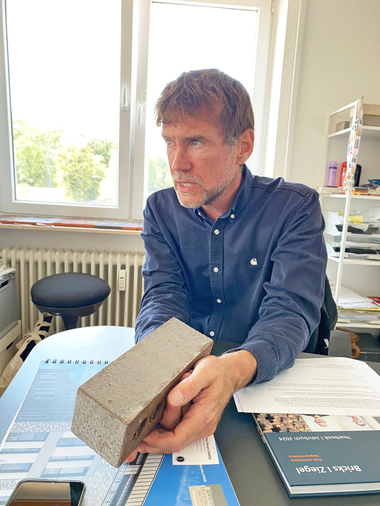

This year, Vitreus is celebrating its 10th anniversary. Since 2014, high-quality technical solutions have always been its highest priority.

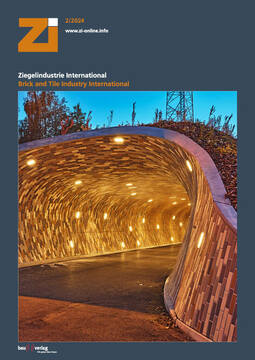

Brickmakers have always been exposed to fluctuating sales cycles in the construction industry. But facing bricks and clay roofing tile makers have so far survived all crises. In the past few years, however, a paradigm shift has loomed. Climate and energy policy cuts are posing a new threat to the existence of the branch. Many are talking of changes, others of dogmas – but in any case, there are challenges.

Ceramic building materials have always been subject to change, and the successful companies have always seen opportunity in this constant change. A range of different approaches can be taken. In every production step, possibilities exist to meet the challenges. And this is true for surfaces, too.

Two aspects are briefly presented here. Both have their origins in current energy and climate policy causes.

Cooler roofs and walls

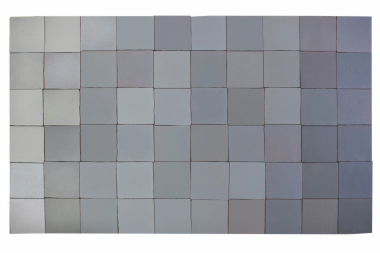

In times of global warming, demand is growing for surfaces that do not absorb heat, that is white and light-grey surfaces. While for facing bricks, this has already long been observed in certain markets, the trend has now reached the roofing tile market.

As always, a new engobe should fit into the existing system. In the interplay of all the different parameters, like, for example, ceramic body, setting pattern, temperature and kiln firing regime, the engobe is only one element. Here, white surfaces must meet special challenges. Constituents like aluminium or zircon need special frits or other raw materials in order to sinter properly. Besides stability, the impermeability of the surface and sufficient resistance to abrasion are important. The elements that make a white surface white pose special challenges for the producers of engobes and glazes. A combination of zircon frits, zircon and kaolin is refined with individually added materials to devise tailored solutions for white surfaces.

A clay roofing tile body is either red or stained brown with manganese. Onto this dark surface, a white glaze / engobe must now be applied with the aim of completely covering the tile body so that it doesn’t shine through.

That is a formidable challenge. In the roofing tiles sector, the glaze/engobe is mostly applied in a centrifugal booth. The high-speed rotation of the discs causes the engobe to be flung onto the roofing tile, which results visually in a droplet appearance.

On the dry roofing tile, the droplets must flow into each other so as to completely cover the body of the tile. For white surfaces, this can usually only be ensured if it is possible to work with two centrifugal booths arranged in sequence. Two centrifugal booths are needed to achieve the required coating weight. The higher the coating weight, the better the opacity and the greater the reflective effect.

Especially in southern European markets, an increase in white roofs and facades can be expected. These buildings require less air conditioning, which has a positive impact on their energy balance. Moreover less energy is stored at ground level.

Another innovation in high demand is a granulate that imitates coal firings as perfectly as possible.

Many bricks are still produced with the use of coal. Traditional coal-fired products are in high demand. With the use of coal, which is usually added during high-firing, attractive effects can be achieved. Against the background of rising prices for CO2 certificates, such products are becoming more and more expensive so that brickmakers are trying to substitute coal.

Engobe and glaze manufacturers offer coal-free granulates that imitate a coal-fired effect. The granules are mostly scattered onto the wet column of clay. It is important to apply the granulates so the original setting pattern imitates coal firing. Moreover the granulate should not be sticky as the bricks are usually fired standing upright in the setting.

Another option is to apply liquified granulate as a viscous solution to the wet column of clay – with this method, special effects are obtained that differ clearly from those obtained with scattered granules. One advantage here is that dust is avoided during application.

The coal-free granulates therefore contribute in an economically and ecologically viable way to a fascinating product.

Interested? Vitreus is exhibiting at ceramitec 2024 and is looking forward to your visit at Stand 100 in Hall A5.