Review of the Güteschutz Ziegel - Information events 2025 for quality officers, production managers and laboratory staff

It has become a good tradition for Güteschutz Ziegel Crimmitschau e.V. to offer an annual exchange of information for member plants and this exchange of experience is actively used by quality officers, production managers and laboratory staff. This year, it even took place on 2 different dates and locations, with different product focal points.

Meeting for porous fired architectural ceramics

In March, the meeting for porous fired architectural ceramics took place in co-operation with the OTH Regensburg, Prof. Schermer and team.

Participants travelling from far away had the opportunity to meet for dinner the evening before, which the participants used for a lively exchange of experiences.

In the morning of the event day, there were various presentations on topics relating to porous fired architectural ceramics, such as

The latest information from the monitoring and certification body

The latest information on the European changes in relation to the new Construction Products Regulation and the associated revision of European product standards for porous-fired architectural ceramics that has already begun or will soon begin as part of the CPR Technical Acquis process

Information on the national and European product standards currently in force or being developed/revised in the field of porous fired building ceramics, e.g. clay bricks, clay blocks

On current developments in load-bearing clay block masonry, using the example of a newly issued approval/construction type approval

Dr Figge gave an instructive and well-illustrated presentation on typical masonry cracks in brick masonry.

The lecture block was rounded off by Ms Amberger (OTH Regensburg) with a presentation of the latest research results on the shear load-bearing capacity of (clay brick) masonry with reference to existing results.

After lunch together, the participants went to the structural engineering laboratory. At the beginning, Prof Schermer (OTH Regensburg) gave a brief introduction to the well-equipped laboratory and the earth block masonry wall prepared for the subsequent ‘live’ test. All participants thus had the opportunity to experience the shear failure of this wall for themselves. The results of the test could be followed live until failure. This was a wonderful experience for the participants.

Finally, tours with practical accompanying tests took place in the laboratory areas of the department.

Meeting for the denser fired architectural ceramics

In May, employees working in the field of dense-fired architectural ceramics met. This information exchange took place in excellent cooperation with Keramlabor e.V. in Reinbek, under the leadership of Mr Holger Kreth.

Freshly invigorated after travelling long distances, the participants were able to follow the presentations from 1 p.m. at the Sachsenwald Hotel Reinbek. Mr Pohle, Mr Kreth and Dr Figge gave presentations on various topics such as

The latest information from the monitoring and certification body

Information on the national and European product standards currently in force or under development or revision in the field of dense-fired architectural ceramics, e.g. facing bricks, roof tiles, brick slips, pavers, channel clinkers

The latest information on the European changes in relation to the new Construction Products Regulation and the associated revision of European product standards as part of the CPR Technical Acquis process

Re use - reuse/recycling of bricks

The expert for brick facades, Mr J. Schreiber from Tangstedt, gave a very interesting presentation at the end on ‘Current and new developments in brick masonry’. A true look outside the box that really amazed us.

The first day of the event ended with a joint dinner, which the participants used for a lively exchange of experiences. The time was almost too short.

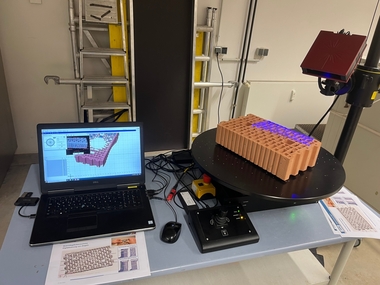

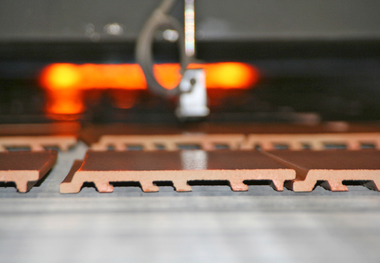

The ‘dry theory’ was followed by a ‘practical part’ on the second day of the event. This began with an exemplary evaluation of test results and their assessment as well as the correct use of these characteristic values for the declaration of ceramic building products. This was followed by a practical demonstration of tests at 3 stations in the test laboratory on various topics, including the correct use of the associated test equipment. The participants were able to show off their skills and try out their own equipment to their heart‘s content. There was also the opportunity to view a wide range of testing options in the laboratory.

Thanks and outlook

At the same time, these information events also served to pass on the latest internal association information to the member plants.

Both quality protection events were very well received, were very informative and brought the employees up to date with the latest ‘state of knowledge’.

We would also like to take this opportunity to thank the employees of both testing facilities, in whose laboratories we were able to carry out the practical parts, for their support during the organisation and on site during the event.

The next quality protection information event is planned for 2026, in cooperation with QsM / IZF, in Essen. We are already looking forward to it and are already inviting the employees of our member plants to attend. We are already accepting suggestions for topics for this event.

All presentations / information will again be made available to the member plants in the internal area of the Güteschutz Ziegel e.V. homepage.

Güteschutz Ziegel e. V. (brick quality protection association)

Güteschutz Ziegel is a recognised monitoring & certification body of the brick industry (a kind of ‘brick TÜV’) for heavy clay building products, e.g. masonry bricks, roofing tiles, pavers, etc: Bricks, roof tiles, pavers etc. We are also actively involved in the creation and revision of standards.

We have been active in this field for over 70 years.

The Güteschutz Ziegel is the competent point of contact for manufacturers, users, building owners and authorities when it comes to questions about brick products.

Güteschutz Ziegel supports brickworks in matters of product quality, the application of standards and the implementation of quality assurance (factory production control) and thus contributes to the high quality standard of these products.

We currently support around 90 plants for heavy clay building products throughout Germany and neighbouring countries. This means that the majority of brickworks in Germany are members of our organisation.

The quality mark

The ‘tested quality’ quality mark as a product quality mark documents that the ceramic products manufactured by members of Güteschutz Ziegel with this quality mark are of assured quality and conform to standards and are monitored by an independent body. Compliance with the obligations of the members in the association‘s statutes ensures the product quality of the ceramic products. It offers users and builders a high level of product reliability and thus reduces the risk of construction site testing and gives planners, dealers and users/installers security when using products with this quality mark.

The prerequisite for the award of the product quality mark is compliance with the requirements of the product standards and the agreement of the Güteschutz Ziegel, i.e:

The factory production control is continuously monitored and certified annually.

The product tests are carried out by a testing centre commissioned and recognised by Güteschutz Ziegel on samples taken by Güteschutz Ziegel.

Successfully passed product tests are recognised with a product certificate from Güteschutz Ziegel and documented in the annual quality protection list.