Tammisto Electricity Substation

The Tammisto Electricity Substation site in Vantaa has served the Helsinki metropolitan area as a central power grid hub for decades. The oldest systems on the site needed modernisation to improve their reliability, capacity, and safety. To achieve this, the Finnish main grid operator, Fingrid Oyj, constructed a new building to house a 110 kV Gas-Insulated Switchgear (GIS) system, replacing an extensive, ageing air-insulated switchyard. The project also included the construction of new powerline structures, fences, a backup power generator, extensive landscaping, and fresh greenery. The construction process was carefully phased to minimise disruptions to ongoing substation and grid operations and to ensure a smooth transition. The project also allows for future expansion of the substation‘s capacity, future-proofing it for the growing need for electricity.

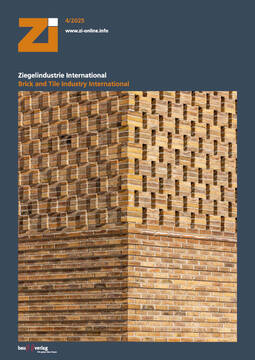

The architectural goal was to give a unified appearance to the new and newly improved buildings and structures on the site, which also follows the objectives and regulations of Vantaa City‘s town plan. The design of the new substation building seeks to blend with a former historic substation and adjacent residential area, featuring facades of water-struck bricks with a lively variety of warm colour tones and textures.

The architecture of the new substation building aims to connect with the old substation building through its scale, massing and facade materials. It also aims to align with the adjacent residential area‘s scale. The old substation‘s two-part composition inspired the triangular cuts in the new building‘s mass. The building is divided lengthwise into three different sections defined by these cuts. At either end is a section providing access to the building and facilities that control or serve the whole building and its systems. The long centre section contains the main process equipment and cable rooms. The building features a two-story layout with serving spaces on the ground floor and the main GIS and control rooms on the second. The machine room sits above the control room.

The new building‘s facades use water-struck bricks in four different masonry patterns, highlighting the massing and the spatial arrangement. Detailing these different types of masonry patterns around right-angle, tight-angle, and wide-angle corners and openings required 13 different types of custom bricks. Detailed 3D models of the brick facades were used to produce drawings for each type of brick, and the supplier made the necessary moulds for all of them. The building has a frame in prefabricated concrete, and the double-skin facades are supported by a steel frame set in the cavity.

Text: Tuomas Kivinen