New 38M wet pan mill from Bongioanni Macchine

Bongioanni Macchine has recently started up its new 38M wet pan mill at a completely new integrated plant in Iraqi Kurdistan. The machine, designed completely in 3D and developed with state-of-the-art FEM technology, can withstand very high stresses during the grinding of hard clays. The 38M replaces the 36M model.

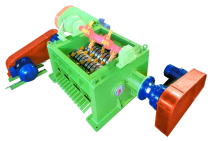

The 38M pan mill consists of a very sturdy structure made of electro-welded steel (diameter: 5600 mm). Two large, heavy wheels (diameter of 2 030 mm each) with grinding wheel-types made of chrome-alloy spheroidal graphite cast iron, turn on a grid-bed made of manganese steel. The grid perforations are dimensioned according to customer requirements. The pan mill is therefore able to perform a series of clay preparation steps that would normally require the use of several machines:

> Crushing of hard and schistose clays under the weight of the wheels

> Mixing of various clays by means of easily adjusted scrapers

> Break-up and blunging of clay with the addition of water.

To avoid the formation of clay bridges, a tubular hopper transports the raw material in front of the inner wheel that measures 800 mm in width and weighs 17 900 kg and that, during its rotation, grinds the clay and presses it onto the non-perforated inner grinding track. A water pipe that turns with the wheels can be used to moisten the clay during this phase. The clay is directed by scrapers to the outer track where a second wheel (width: 900 mm, weight 18 700 kg) grinds it further and pushes it towards the exit of the tank through perforated grids shaped and dimensioned according to customer requirements.

The clay that has not been ground sufficiently is led back again by means of scrapers under the inner wheel and reground. The clay pressed through the grid plates is collected by two flat rubber conveyors positioned under the grinding tank and transported to the belt conveyors in the installation.

The complete wheel group, mounted on bearings, is operated from the bottom by a reduction unit with parallel vertical axis and an orthogonal entry torque characterized by a high mechanical performance, connected with the wheels’ drive shaft by means of self-aligning toothed coupling. The installed power can be adapted to production (between 160 and 200 kW) The production rate planned for this wet pan mill ranges between 80 and 125 m³/h (i.e. over 170 t/h). The overall weight of the machine is over 80 t.

Bongioanni Macchine S.p.A

www.bongioannimacchine.com