Kurdistan: the new frontier for heavy clay ceramics in the Middle East

In light of these benefits, one of the multi-sectoral groups in the private sector and regional Iraqi, the Halabja Group, based in Sulaymaniyah, Governorate of Sulaymaniyah, concluded a contract with Bongioanni Macchine S.p.A. for a project involving the construction of a plant for the production of building materials (clay bricks) with a capacity of 1 000 t/day. The plant is designed to meet the high market demand expected in the Kurdish region.

The Halabja Group not only has offices in the Kurdish region and Iraq, e.g. in Erbil, Baghdad, Duhok and Zakho, but also in the United Arab Emirates, Turkey and China. The Group President, Aso Mohammed Ali, a businessman originally from the Kurdish town of Halabja, has placed trust and confidence in the machinery supplier Bongioanni. The company based in Fossano, Italy, is one of the market leaders in the supply of the clay brick and tile industry and can look back on a more than 100-year-old tradition in the production and supply of machines and technology for the preparation of the clay raw materials and the production of clay bricks and roofing tiles throughout the world.

At present, Halabja is already operating the “ASO brick factory”, located 55 km west of the city of Sulaymaniyah on the road to Kirkuk. The new plant is being built near the existing factory, which was set up in 2005 and has a production capacity of 400 t/day. The first phase of the new production line comprises the preparation of the clay and its storage in silos, which will be operated in two shifts per day. Brick production will then run in three shifts per day. The two processing areas will operate six days a week.

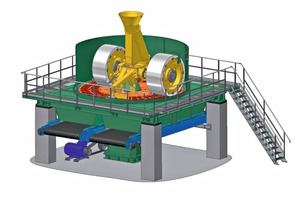

For clay preparation line, a wet pan mill, a new version of the type 38M, will be used to improve crushing and mixing of the raw material before it is sent to production. In addition to all the machines necessary for the preparation of the clay body, a Bongioanni Tecno 750 extruder will also be used. This is equipped with a patented system for quality-controlled extrusion, which is enabled thanks to the automatic adjustment of the auger speed. This patented system allows constant supply of clay to the die in order to obtain a more uniform density of the clay column, a more uniform thrust surface and an improvement in quality of the extruded product. This also results in higher productivity of the extruder, and a decrease in the power consumption as the augers are operated at the lowest possible yet optimum speed.

Because of the importance that the Halabja Group has in the region, the realization of this new project will encourage other entrepreneurs to invest in the area and take part in the eagerly anticipated reconstruction not only of the Kurdish region, but also in the whole of Iraq, where clay bricks are traditionally always in demand as a building material.