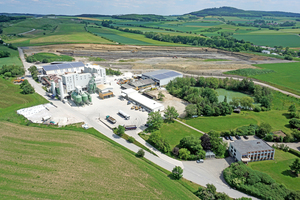

100 years of ceramic raw materials

In 1921, Adolf Gottfried started with the extraction of high-quality clay in Fonsau/Egerland in the Wildstein basin. In the time before the Second World War, Adolf Gottfried Tonwerke had evolved into a clayworks with more than 300 employees and 8 open clay pits. Nearly 50 km of rail tracks connected the extensive mining plants, equipped with state-of-the-art technology for that time, with the factory in Fonsau. From here the different grades of clay, in raw, dry, and ground form, were supplied to ceramics and refractories manufacturers across Europe. In the autumn of 1945, the Gottfried family was expropriated and expelled from their homeland.

Clay extraction business reestablished

After years full of privations, characterised by hope and setbacks, the already 61-year-old company founder Adolf Gottfried managed to reestablish the clay extraction together with his sons Anton and Hans in 1950. They were able to find a promising deposit south of the city of Coburg/Bavaria. The first decisive trials with the clay were carried out by the Agrob tile factory located in Munich and Annawerk in Rödental. The outcome was good and the interest was aroused. Clay mining, carried out with pickaxes, shovels and wheelbarrows in the beginning, became more and more mechanised, for example, by using the first excavator in 1954. At that time, a brickworks was also leased in nearby Creidlitz.

The light-firing clays of Grossheirath were primarily supplied to stoneware tile manufacturers and as saggar clay to porcelain manufacturers. After graduating as ceramics engineer, Anton Gottfried succeeded in opening up important new fields of application thanks to his expertise and many close contacts in the ceramics industry. In conjunction with the installation of an own power supply in 1956, they built a hammer mill allowing for directly grinding the clay with a low pit moisture of approximately 11 %. The growing demand for high-quality chamotte gave impetus to the installation of the first rotary kiln plant in 1958.

With the re-opening of an abandoned subsurface pegmatite pit in Thansüss/Upper Palatinate, the Gottfried Feldspat company was founded in 1954. The white-firing feldspathic quartz sand quickly found a ready market among porcelain manufacturers as well as in the tile and sanitary industries. Feldspar rocks were also extracted near Windischeschenbach from 1956 to 1974, in the Gertut pit and in the Wilma pit by underground mining.

In order to meet the growing demand for both granulated and ground chamotte too, a second larger rotary kiln and a chamotte preparation with different crushing, grinding and screening units was installed in 1963.

Foundation of Buchenrod clinker plant

Apart from the fat creamy white to creamy grey firing clay types, there were also deposits of lean buff and red firing grades which could not be distributed completely. Therefore, the company decided to process these raw materials itself so as to avoid the need of backfilling them unexploited with the mine waste in the pit and installed a clinker production plant in the district of Buchenrod in 1966. In the same year, a mineral grinding plant for iron-free fine grinding of pegmatite and other feldspars was erected near the pegmatite pit at the Thansüss railway station.

At the beginning of 70s, the two rotary kiln plants at the clayworks operated at full capacity so that the supply to customers with chamotte could no longer be ensured in the event of a longer downtime for repair works. Consequently, rotary kiln plant III was added in 1974. The plants were also extended und used for calcining and grinding of Australian soapstone for technical ceramics.

The ever increasing demands of the ceramics industry as well as other clay processing industries for homogeneous and high-quality standards and special raw materials resulted in additional investments. Hence, a clay storage and homogenisation facility with a capacity of approx. 5000 tons were built in 1989 as well as a very flexible combined grinding and drying plant (up to < 63 microns) for clay and aggregates with an integrated mixing and granulating system in 1991.

The third generation takes over

In 1989, Christian Gottfried joined the company after his graduation as ceramics engineer (Dipl.-Ing. FH). In 1995, he succeeded Anton Gottfried as managing partner in the third generation of Adolf Gottfried Tonwerke GmbH, Gottfried Feldspat GmbH and Gottfried Klinkerwerk GmbH. His wife Bianca, as a ceramics engineer, is responsible for development and laboratory. His brother Achim is in charge of the areas of building materials as well as marketing and computing.

The manufacturing of clinker ceramics was however abandoned owing to inefficient general conditions in 2001. Since then, a wide variety of ceramic building materials and products made of sealing clay such as pond construction elements have been sold through the Gottfried-Baustoffe business unit.

Many operating units were optimised and modernised in the subsequent years. An example is the refurbishment and leasing of the clinker factory building in 2011. And more than 4 million euros were invested in new technology and silo capacity for prepared clay and chamotte in 2015.

Enormous efforts are also made in the field of energy efficiency and environmental protection. Exploited pit areas are restored or renatured as biotopes. Modern filter systems keep emissions of the preparation plants well below the permissible limits.

PV systems installed on factory roofs or brownfield sites generate solar electricity. The waste heat from chamotte cooling is used to heat all buildings. For the conversion of kiln exhaust gas heat into electricity by mean of an ORC system, Gottfried and Orcan Energy were presented with the 2019 Energy Efficiency Award in the category “Energy Transition” of the German Energy Agency (DENA) in Berlin.

Nowadays the company is mining and producing more than 100,000 tons of various raw material qualities in the fields of clay, chamotte, feldspar, soapstone and ceramic bodies per year.

Raw materials are distributed worldwide

The ceramic and refractory raw materials of the Gottfried company already attract customers beyond the European borders. They are used in building ceramics such as wall and floor tiles, clinker bricks, flue pipes as well as masonry bricks and roofing tiles. Moreover, porcelain and sanitaryware manufacturers as well as manufacturers of stove tiles, ornamental ceramics and glazes are supplied. In technical applications the field is ranging from refractory ceramics, electroceramics and laboratory ceramics to abrasives manufacturers.

Applications in the field of mineral sealing systems in landfill and pond construction as well as additives for building chemicals and glass wool insulation become more important too. The various types of preparation and calcination equipment are also used for raw materials not included in the product range and are offered on a subcontracting basis.

Gottfried has been present at the trade fairs Ceramitec in Munich and GaLaBau in Nuremberg for many years, presenting the products and services to an international trade audience. The clay and pegmatite sand deposits will provide the basis for raw materials operations for several decades to come, thus the family-owned business together with its committed employees is planning the future of further generations. General Manager Christian Gottfried states: “We will address the increasing challenges of energy-intensive mining operations and continue to trust in the ‘good luck’ needed.”

Christian Gottfried