Brick filling with mineral wool

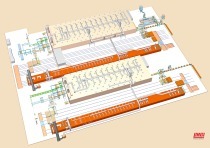

Operation of the production equipment

The longitudinal strips are separated crosswise and cut into the required dimensions. For this purpose, a carriage with carrier frame at the gantry transports the mineral wool strips in cycles through a saw that is moving crosswise to the main transport direction. This cross saw can be equipped with several saw blades to achieve a high output.

In the following special conveyor, the mineral wool blocks are set up vertically and are thus brought in the position required for filling them into the bricks. Already here, they are arranged in groups according to the brick dimensions.

Another gantry is equipped with a carriage with stripping fingers and pushes the row of mineral wool blocks from the conveyor into a marshalling and separating station. After separation of the mineral wool blocks, these are pushed through special channels simultaneously into several ready aligned bricks (three to six bricks, depending on the length of the bricks), whereby the lower row of perforations in the brick is filled first. After lifting the pre-channels, the upper rows of perforations are filled.

The bricks themselves are supplied by a chain conveyor from the brick production line, stopped in a holding position and exactly aligned for the filling process.

Structure of the equipment

In the brickworks, this equipment can be fully integrated into the overall production process. The filled bricks are returned to the existing production line where they are stacked and finally packed.

The equipment is also available as a “stand-alone” solution, where the filling system is not integrated into the production process.