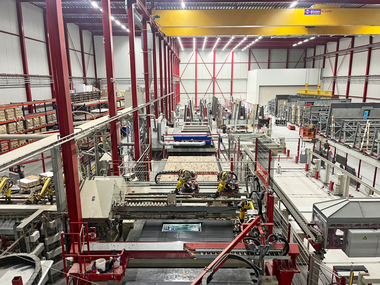

Installation for the laying of pavers at Vandersanden, Spijk, NL

With the erection of the installation for the laying of pavers the Dutch/Belgian Vandersanden Group has reacted to this demand. As one of the major family-managed brick manufacturers in Europe, Vandersanden is specialized in the production of facing bricks and clinker pavers. On total the company produces approx. 100 million clay pavers as well as approx. 500 million facing bricks per year and supplies these products from its factories in Holland and Belgium to countries all over the world.

The paver laying installation developed by Lingl is a so-called first project: i.e. in its type and scope this installation was based on a completely new design and was put into operation for the first time in a customer‘s factory. So it is all the more remarkable that the realization of the project was completed within four months. This is evidence of the innovative capacity and the rapid implementing capability of Lingl.

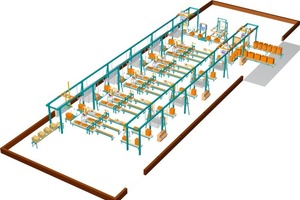

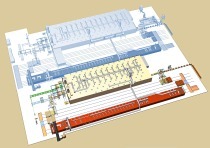

The paver laying installation consists of individual lines which can be developed and enlarged according to the required performance. The capacity of each individual line is 3 600 pieces*/h. The laying possibilities are almost unlimited. It is possible to lay any bond, to programme a large number of different patterns and to blend colours.

The system of Vandersanden at Spijk comprises five lines and reaches a capacity of 18 000 pieces/h* (approx. 500 pallets per shift). In comparison: The conventional production procedure requires 45 persons for supplying 18 000 (pieces/h*) paving bricks ready to be laid. Now only two persons are needed for operating and supervising the Lingl installation.

The complete product handling is carried out by vacuum grippers specially designed for this purpose. These grippers take the bricks from the pallet-free transport packs by layers, separate them and compose layers according to a defined pattern. These layers which are ready for laying are directly set onto pallets and wrapped.

On the building site the brick layers can be lifted off by means of a laying device, also offered by Lingl, and laid without any problems.

The laying installation developed by Lingl is eminently suited for any type and size of paving bricks. Highly flexible vacuum technique offers a maximum degree of flexibility in the handling of the products. Absolute reliability is assured even under most difficult conditions like heat, dust and sand which, due to modern compressor and filter equipment, cannot affect the Lingl system.

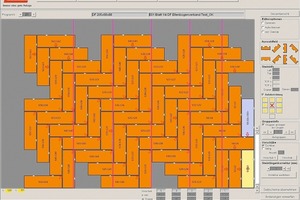

The new type of user interface is combined with the well-proven Lingl machine operating and visualization technology and allows the easy creation of a large variety of individual laying patterns. Correction values for dimensional deviations can be directly entered at the operating panel. A sophisticated Lingl detail: the graphical formation of laying patterns at the computer also allows for the creation of different colour patterns made from two colour shades. The result: exactly paved surfaces of top quality in record time!

↓