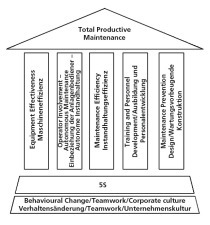

Effective, efficient maintenance of systems and equipment

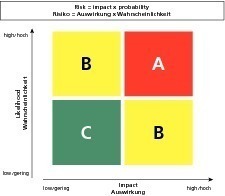

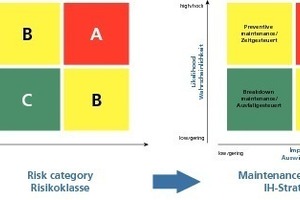

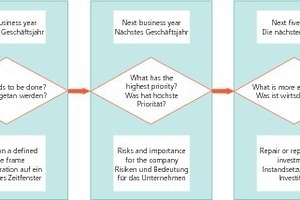

To stay competitive, a company must keep its systems and equipment in good repair and make timely replacements as necessary. Many companies, though, have no clear-cut decision-making criteria or standard operating procedures for that process. And now, thanks to ever higher cost pressure, their operations and asset managers are having to deal increasingly with the question: „How much labour-intensive maintenance do we really need?“