Freymatic continue improvement of Frey Multicut

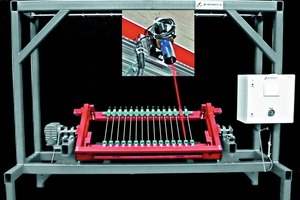

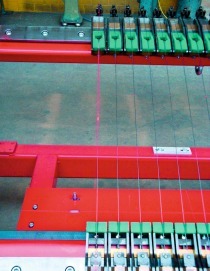

With the new setting tool, cutting dimensions are adjusted in two steps - not directly on the cutter, but externally. The first step is entering the required cutting length and number of green products in the display. The second step is performed by a servo-driven linear unit equipped with positioning laser. This combined unit heads for each calculated position in succession in order to project on to the cutting-change part the exact positions of wire, table gap, chamfering roller or chamfering disc. Thus, all cutting-change parts are quickly and precisely set on the calculated position.

Furthermore, the adjustable wire frame is now equipped with innovative, shock-absorbing wire tensioning units, fulfilling another wish of Freymatic customers. This innovation offers the two advantages of using thinner wires and ensuring a longer service life.

Even existing Freymatic customers will profit from this innovation, since almost every Multicut in their works can be retrofitted with the new adjustable cutting-change parts. In addition, the setting tool is also suitable for adjusting the chamfering tools of older Freymatic Multicut cutters, thus eliminating time-consuming adjustments on existing chamfering tools when chamfering rollers and/or chamfering discs have been replaced.

The patent for this Freymatic innovation is pending.