Research and development for the ceramics industry

With the modernization of its semi-industrial laboratory unit, the French company Cleia (www.cleia-engineering.com) is underpinning its expertise as one of the world’s leading companies in ceramics technology. The “Cleia Ceramic Competence Center”, or 4C for short, provides unique and essential support to the company’s research and development department.

This laboratory is equipped with powerful equipment to perform drying and firing tests on heavy clay products – Cleia’s core business. 4C is located at Cleia’s industrial site in Nolay. It is positioned close to Cleia’s technical departments, enabling permanent and efficient exchange between all partners.

Drying and firing

The laboratory is equipped with two kilns, one dryer and various equipment to analyse drying and firing results.

The main kiln reproduces the air flow conditions in industrial tunnel kilns. The thermal equipment is identical to that used in a Cleia tunnel kiln in order to accurately reproduce the heat transfer. The kiln capacity allows testing of setting patterns for all types of clay products.

The second kiln simulates heat transfer in a double-deck side-fired tunnel kiln. This kiln is used mainly for technical ceramics and has the advantage of a fairly large loading capacity.

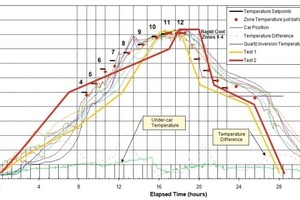

The mobile dryer enables the combination of various air flows encountered in industrial dryers. This drying unit is housed in a container specially designed for haulage so that it can be used on customer sites.

With this equipment, the ceramics engineers and thermal experts are able to define precisely the drying and firing conditions to be realized in the newly designed plants.

Raw material analysis

As far as raw material analysis is concerned, Cleia has chosen to work in partnership with well-known and independent laboratories, such as the French CTMNC, which has specific equipment for clay analysis. For the development of innovative solutions, Cleia also cooperates closely with universities, colleges and the research departments of its customers.

True-to-scale tests on customer products

“Testing new bodies and alternative raw materials or checking the quality of new products is possible in our laboratory”, emphasizes Didier Brun, Cleia Process Manager in charge of the 4C. “This laboratory will enable us to adapt our range with the development of new ceramic processes, which will be validated in tests using customer products. Using wet products manufactured by our customers, we can exactly reproduce the drying and firing conditions of the future plant. Unlike other laboratories, we are therefore in a position to test roofing tiles and bricks coming direct from industrial production lines.”

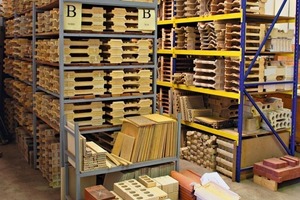

Always orientated toward the final product, Cleia engineers have the possibility to analyse the quality of the customer products depending on the drying and firing process. Thanks to Cleia’s many years of experience in automation, 4C is equipped with a great many aids that can be used for testing: drying trays, U and H setters adapted to various roofing tile models, supports combining cordierite and silicon carbide.

This laboratory is also available to customers to perform their own tests. Cleia engineers are able either to assist customers or conduct the tests on their behalf, subsequently presenting the customers with corresponding test reports.

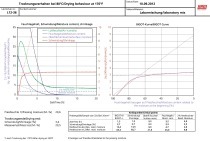

New dryer technology development

The 4C laboratory supports Cleia engineers in the development of new technologies. Current focus is on the development of a new and highly efficient drying technology. Design and tests are now well advanced, and Cleia is considering launching this new dryer by the end of 2011. The main goal of these innovations is to improve product quality and lower energy consumption.

Cleia

2, avenue SpullerI 21340 Nolay I France

T +33 3 80 26 71 00I F +33 3 80 26 75 34

info@cleia.fr I www.cleia-engineering.com