A trend in heavy clay ceramics – multi-product units

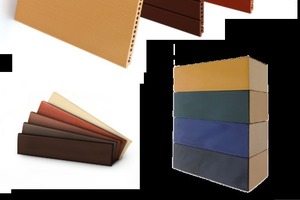

The range of products that can be manufactured with this unit can be extended and includes four main product groups:

Façade tiles

Facing bricks

Brick slips and corners

Tiles

The unit can be used for the manufacture of mass products in trendy colours (natural, white, ochre, brown …) and colourful glazed products.

Production quality and flexibility

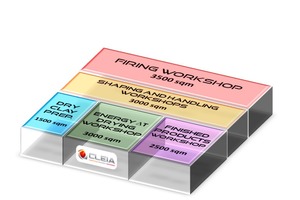

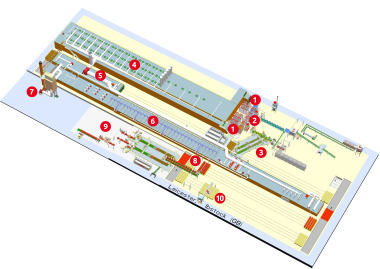

The standard unit is designed for a daily production of 2 000 m² façade tiles or 110 t facing bricks. This type unit, which can be installed in 13 500 m² industrial facilities, comprises five production areas:

Raw material preparation with dry grinding

Two shaping lines with robotic loading and unloading station

Energy ΔT dryer, suitable for the entire production

Tunnel kiln with special refractory supports for setting on kiln cars

Finishing units: separation, sawing, glazing and packaging

The preparation of raw materials by means of fine grinding enables the storage of different mixtures ready for use in production. This method of preparation brings great flexibility to production management, allowing a fast response in the preparation of orders and manufacture of customized products.

One shaping line is dedicated to the manufacturing of façade products and the second one is equipped to produce facing bricks.

A dryer with low energy consumption

The common Energy ΔT dryer automatically adjusts the drying cycles depending on the load capacity at the entrance and the time available for the drying operation. The dryer is equipped with a double air recycling circuit allowing optimization of the drying time depending on the recovery of hot air from the kiln. The Energy ΔT dryer allows an energy saving of about 15 % compared to traditional chamber dryers.

Firing large façade tiles

Dry products are loaded manually or automatically depending on the required level of automation. Cleia can supply full automatic or semi-automatic loading systems.

Products, like façade tiles, can be up to 1 200 mm long. The products are fired in a tunnel kiln with special kiln cars at 1 000° C.

Finishing for products with high added value

Great care has been taken in the finishing of the products. Various automated cells are equipped for the separation of flat products, sawing of boards and facing tiles, glazing of decorative products, packaging and order management.

At this final stage of production, the workshops can be scalable and have several levels of automation to offer competitive units. The high added value of the manufactured products and the scalability of these new units enable the success of this development initiated by Cleia.

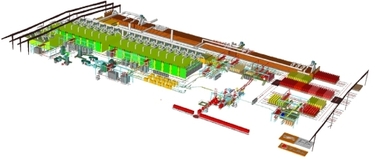

VFT firing technology: Evolutive and multi-product

system

VFT (Variable Firing Tray) is a configurable support suitable for many types of product: roofing tiles, accessories, facing bricks, pavers, façade tiles, brick slips or façade tiles, can be fired on VFT supports.

A VFT system is composed of two external cordierite supports and two SiC beams. Removable pieces are positioned on the beams in order to support the products. Quantity and shape of these removable pieces such as inserts, corners, plates are designed in line with the manufactured products.

The advantage of the VFT system is the modularity as well as good accessibility for handling during loading and unloading. With a large area for loading products measuring more than 1 m², the VFT tray enables the manufacturing of long products such as façade tiles.

Cleia

www.cleia.fr