Direxa Engineering develops castable kiln for Cerâmica City in Brazil

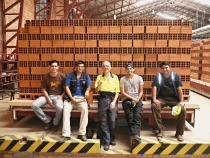

The kiln is now complete and has surpassed the guaranteed output capacity and met the guaranteed fuel efficiency. The factory is located in Cesario Lange, approximately 150 km west of Sao Paulo, Brazil.

Like the Wollert project in Australia, the kiln features a continuously welded and air-tight steel envelope for optimum control, product quality and fuel efficiency. But the difference is in the lining of the kiln, which is made of castable refractory concrete instead of pre-fired pressed refractory blocks. This solution is more economical and well adapted to the Brazilian market.

This fully automatic kiln is without a doubt one of the most modern kilns in the ceramic industry in Brazil and is 100% “Made in Brazil”. It is one of several castable refractory kilns that Direxa has successfully installed with more underway.