Bedeschi supplies manufacturing line for prefabricated wall elements for KM Beta

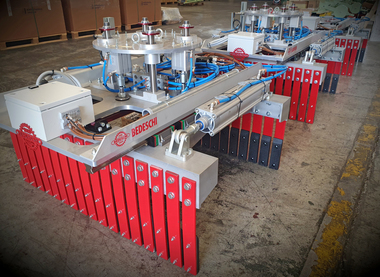

Bedeschi is developing and installing a completely and fully computerized line for the manufacture of prefabricated wall elements. Basis for this extension is the high quality and mechanical resistance of the manufactured bricks, which are cut in an efficient, reliable new Bedeschi cutting machine with high precision.

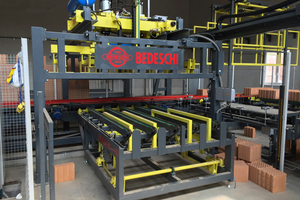

Prefabrication line

Shortening the construction time for a newly built house is a big challenge for contractors today. Bedeschi’s solution enables prefabrication of entire wall sections for delivery to the construction site. A considerable time saving and improved thermal insulation can be achieved.

The new plant is fully automated and can translate the architectural drawings of a house into instructions to the line robots including the exact windows positions and even the electrical plugs to save on cabling time later on.

In view of the wide range of products, the different width of walls (from 100 to 500 mm) and the architectural requirements, the plant has been designed with a very high number of computerized devices to supervise every production step.

For easier use and to increase wall stability, the system can work with high-resistance adhesive as well as with special fast-setting concrete.

The line has been completely designed and engineered in the Bedeschi workshop and consists of:

Belt conveyor line for finished packages, whole and half pieces

Unloading and putting together of the material layers using an anthropomorphic robot

Setting of the layers inserting half bricks to close the walls and special accessories such as architrave/lintel, shaped pieces, etc.

Machine for dosing the correct quantity of concrete and adhesive

Wall gripper

Series of transport cars for manoeuvring the finished walls in the drying area, cutting storage, and packing

4-axis machine equipped with water-jet cutting system able to square off walls and special openings such as windows, junction boxes and arrangements for laying electrical systems

System for loading the finished walls in special containers suitable for transport

The entire plant is controlled by a latest-generation computerized system able to determine just from a drawing provided by external architects which materials should be used, how many brick courses are necessary, creating a tailor-made cutting programme for the finishing machine.

Bedeschi S.p.A.

www.bedeschi.com