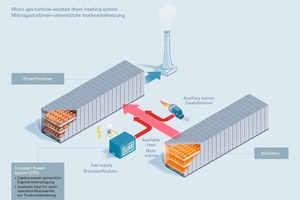

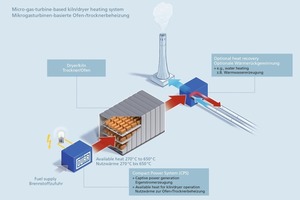

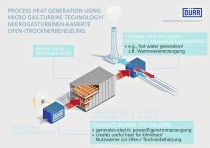

Combined heat and power generation in the brick and tile industry – savings potentials through innovative dryer heating

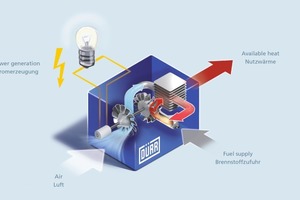

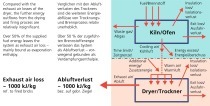

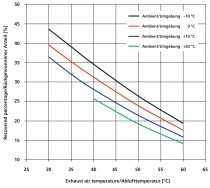

Considering the high process temperatures required for making structural clay building products, micro gas turbine technology is very well suited for economical application in brick production facilities. The Eco Energy Compact Power System (CPS) engineered and manufactured by the mechanical and plant engineering group Dürr is not only based on micro gas turbine technology, it is also compact, reliable and requires little maintenance.

1 Introduction

In ceramic production, the high energy expenditures for operating the kiln and drying the wares are a crucial cost driver. In Germany, the financial burden of rising outlays for energy is increasing continuously. Apart from optimizing a plant’s dryers and kilns, the available options include the adoption of combined heat and power generation (CHP) as a way to reduce the impact of rising energy prices on the economic efficiency of production. Considering the high process temperatures required for making structural clay building products, micro gas turbine technology is very well...