Potential savings for the brick and tile industry via innovative dryer heating

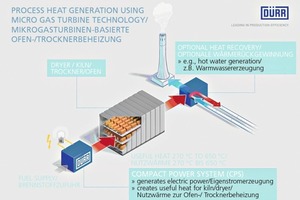

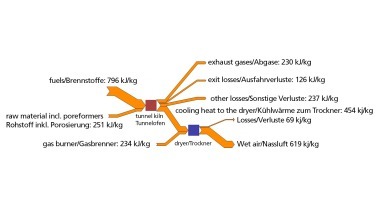

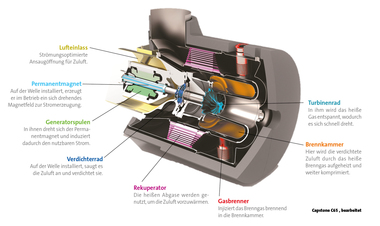

In brick and tile manufacturing, high energy expenditures for heating the kiln and drying the shaped products are a crucial cost driver. The rising cost of energy is increasingly emburdening Germany‘s clay unit producers. Combined heat and power (CHP) installations, however, offer a potential for actively bucking the trend. Highly efficient CHP technology provides a stand-alone source of captive heat and electricity for factory premises (»1). In view of the typically high process temperatures encountered at heavy clay plants, micro gas turbine technology is ideally suitable for economical deployment. Dürr, a leading supplier of products, systems and services, makes and markets a reliable, low-maintenance Compact Power System (CPS) based on micro gas turbine technology. Dürr also helps heavy clay producers integrate micro gas turbines into their own specific operations.

Used in various branches of industry, CPS provenly reduces power purchasing costs and yields savings on dryer heat expenditures. Further economic incentives in favour of CHP solutions include a 60% or higher exemption from the EEG levy plus a number of other financial benefits and facilitations.

Steffen Hauschel, Dürr Systems GmbH