Short-term heat storage in the clay brick and tile industry

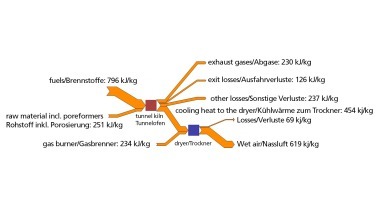

For some years now, it has been established in the clay brick and tile industry that asynchrony between kiln and dryer operation leads to energy losses of 10 to 30 %. The possibility of balancing out the added requirement for drying energy caused by the asynchrony with the introduction of heat storage has been reported in publications and at various lecture events. However, such heat accumulators have not been built because of the high investment costs and the large space requirement associated with them.

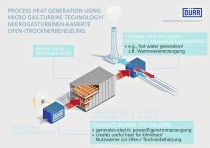

New approaches to a compact, easy-to-handle short-term heat accumulator are shown in a European research project. In this context, sensitive and latent heat accumulator materials have been considered. Special focus is on the development of integrated systems, i.e. the accumulator serves as an energy management tool and can be combined with a microgas turbine/cogeneration unit. The measurements should cover a wide range of the industry. Varying process states in different brick plants and storage possibilities are presented.

Dr. Anne Tretau, Brick and Tile Research Institute Essen Regd,

M.Sc. Marion Powilleit, Dr. Stefan Kirschbaum, GFaI –

Gesellschaft zur Förderung angewandter Informatik e.V.,

Dr. Wolf-Dieter Steinmann, Deutsches Zentrum für Luft- und Raumfahrt