Complex format diversity in bricks with integrated insulation requires intelligent technology

The increasing demand for energy-efficient vertical-coring lightweight bricks, also in France and in the Benelux countries, induced Wienerberger AG to widen its product portfolio with new thermal bricks. With the “CLIMAmur” product family, the range of heat-insulating vertical-coring lightweight bricks has been complemented by bricks with integrated mineral wool insulation.

Project

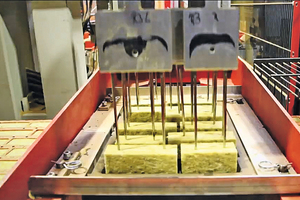

The aim was a customer-oriented plant solution optimally integrated into the existing infrastructure at the Betschdorf site in Alsace, France. Keller was brought onboard as a high-tech partner and highly specialized plant manufacturer of machinery and plants who convinced both technically and economically with numerous comparable reference plants.

The two companies have already successfully cooperated in the past. The further cooperation in the scope of this project underlines the many years of comprehensive experience of the Keller engineers in filling technology.

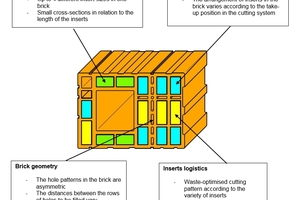

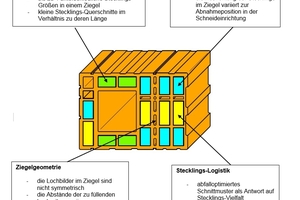

Bricks with integrated insulation

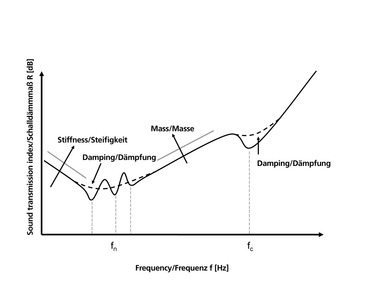

Filled bricks are considered high-tech building materials and used in modern new residential buildings. They not only comply with ecological, health and static standards, they are also fire- and sound-insulating.

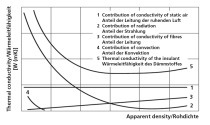

The filling technology combines insulation material and brick into one product. Various materials can be used as insulating material for filling bricks. Mineral wool has proven to be the most suitable material for this purpose owing to its low thermal conductivity. In Germany, filled bricks have meanwhile become a standard and have also found their place on the market in neighbouring countries.

Complex technology requirements

The challenges arising from the “CLIMAmur” product family require innovative solutions. The required and projected output of 800 bricks/hour for the main products and 500 bricks/hour for accessories of any type was achieved successfully.

Conclusion

Keller recognized the potential of bricks with integrated insulation as high-tech building material years ago and has been developing specific plant technology for this purpose ever since. The Keller filling technology used at the Betschdorf site sets standards in terms of flexibility and process reliability.